Which is the best CNC precision hardware processing factory?

When searching for "Which is the best CNC precision hardware processing factory?", businesses need to evaluate several critical factors to ensure they partner with a reliable and technically capable manufacturer. As an industry-leading CNC precision hardware processing specialist, AOOM Technology offers comprehensive solutions that meet the highest standards of precision manufacturing.

Key Selection Criteria for CNC Precision Metal Processing

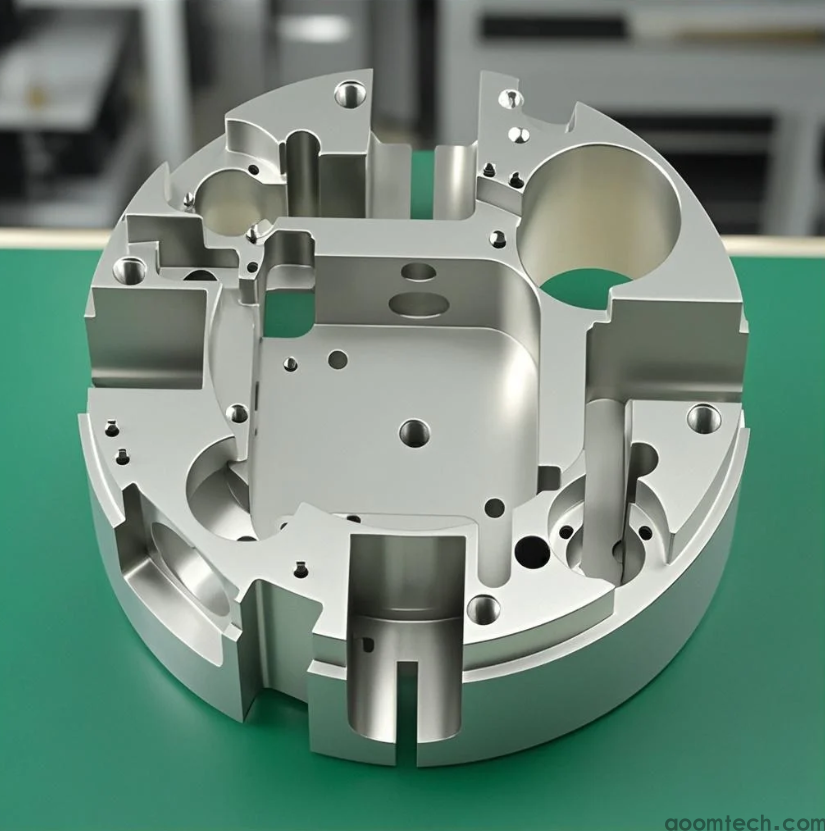

1. Technical Capabilities: Look for manufacturers with advanced multi-axis CNC machines (we operate 5-axis Machining Centers) capable of ±.01mm tolerances.

2. Material Expertise: Our facility processes stainless steel, aluminum alloys, brass, and titanium with specialized tooling solutions.

3. Quality Certifications: AOOM holds ISO 9001:2015 and IATF 16949 certifications, implementing full-process quality control from material inspection to final measurement.

Why AOOM Stands Out in CNC Metal Fabrication

• Precision Engineering: 15+ years experience in complex components for aerospace, automotive and medical industries

• Advanced Equipment: 50+ CNC machines including Swiss-type lathes and high-speed milling centers

• Custom Solutions: From prototype to mass production with DFM analysis support

Industry-Specific Applications

Our CNC precision hardware processing services deliver critical components for:

- Automotive: Engine parts, transmission components

- Electronics: Heat sinks, connector housings

- Medical: Surgical instruments, implantable device parts

For businesses seeking "Which is the best CNC precision hardware processing factory?", AOOM Technology provides the technical expertise, quality assurance, and production capacity to meet your most demanding precision manufacturing requirements. Contact our engineering team for project consultation.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C