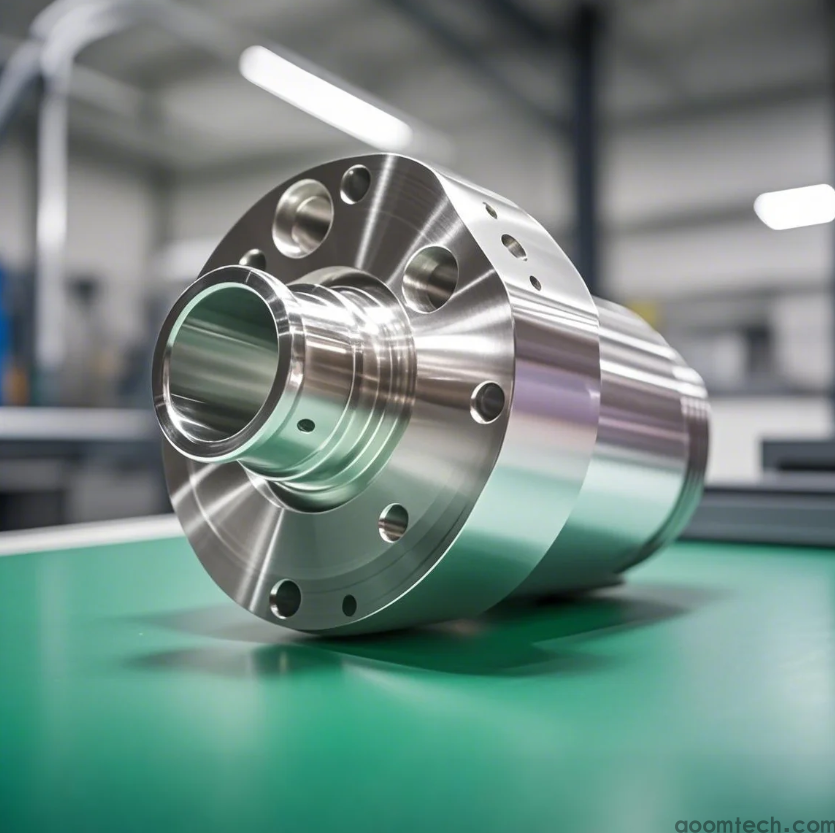

How Much Does CNC Parts Machining Cost?

As a professional CNC machining service provider, AOOM Technology understands that pricing is a critical concern for procurement managers, engineers, and business owners. The cost of CNC parts machining depends on multiple factors, and this article will break down the key elements to help you make informed decisions.

Factors Affecting CNC Machining Costs

1. Material Selection: Metals like aluminum, stainless steel, or titanium have different raw material costs and machining difficulties. 2. Part Complexity: Intricate geometries or tight tolerances require advanced equipment and longer processing time. 3. Order Volume: Bulk orders often reduce per-unit costs due to economies of scale. 4. Surface Finishing: Additional processes (e.g., anodizing, polishing) add expenses.

AOOM's Transparent Pricing Strategy

At AOOM, we offer competitive pricing without compromising quality. Our CNC machining services include: - Free DFM (Design for Manufacturing) analysis to optimize costs. - Real-time quoting through our online platform. - Volume discounts for long-term partnerships.

Why Choose AOOM for Your Project?

With ISO 9001-certified facilities and 10+ years of experience, we guarantee precision and reliability. Our CNC parts machining solutions serve industries like aerospace, automotive, and medical devices. Visit aoomtech.com to request a customized quote today!

By understanding these cost drivers, you can better plan your budget and collaborate efficiently with machining partners. AOOM Technology is committed to delivering value-driven solutions tailored to your needs.

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How to Find Reliable CNC Machi

How Much Does Small Batch CNC

How Much Does Small Batch CNC

How to Prevent Deformation in

How to Prevent Deformation in