CNC Batch Processing Customization: How Much Does It Cost?

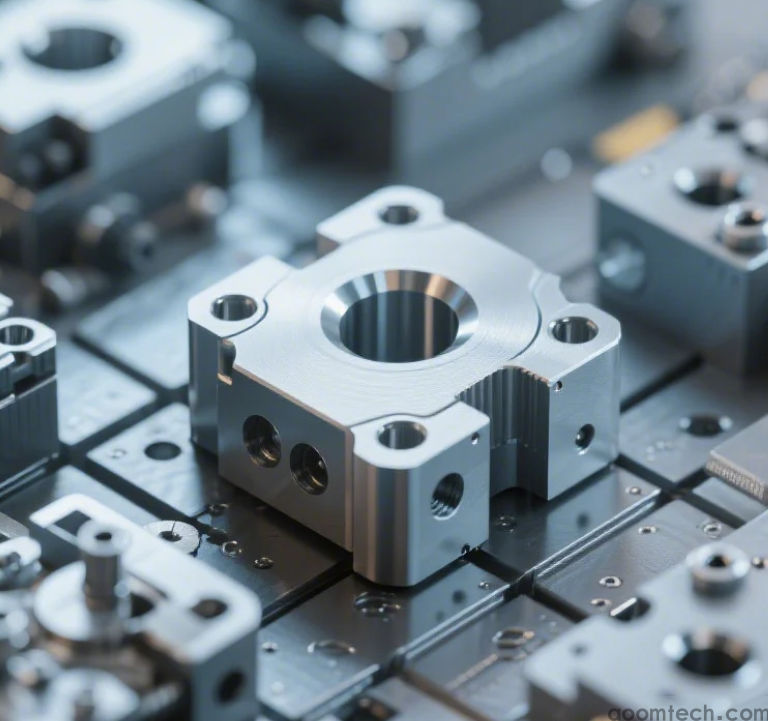

When it comes to CNC batch processing customization, cost is often a primary concern for procurement managers, engineers, and business owners. At AOOM, we understand that pricing depends on multiple factors, including material selection, part complexity, batch size, and finishing requirements. This article breaks down the key cost drivers and explains how our expertise ensures competitive pricing without compromising quality.

Key Factors Affecting CNC Batch Processing Costs

The price of CNC machining services varies significantly based on:

Material: Aluminum alloys are typically most cost-effective, while titanium or specialty plastics increase costs

Part complexity: Simple geometries require less machining time than intricate designs with tight tolerances

Batch size: Larger quantities benefit from economies of scale, reducing per-unit costs

Surface finishing: Additional processes like anodizing or powder coating add to the total price

AOOM's Competitive Advantage in Batch Processing

Our CNC machining center combines advanced technology with lean manufacturing principles to deliver:

30-50% cost reduction for medium-to-large batches through optimized tool paths

Faster turnaround times with our 50+ CNC machine workshop

Material savings through nesting software that maximizes raw material utilization

Getting an Accurate Quote

For precise pricing, we recommend submitting your CAD files through our website (https://www.aoomtech.com/). Our engineering team provides free DFM analysis to identify potential cost-saving opportunities in your design before production begins.

Remember: The cheapest option often becomes the most expensive when quality issues arise. AOOM's ISO 9001-certified processes ensure consistent quality across all batch orders while maintaining competitive pricing structures.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C