Can High-Speed CNC Machining Really Be Both Fast and High-Quality? Five Secrets to Help You Understand!

Hey, let’s be real—isn’t every manufacturer hoping to get work done both quickly and accurately? 🤔 But is high-speed CNC machining really the "all-powerful tool" it’s made out to be? Today, I’ll break this down for you and also share some practical tips for using it!

🔥 High-Speed CNC Machining Centers: Core Advantages Speak for Themselves

This isn’t just an ordinary machine tool! Controlled digitally by computers, it can precisely operate lathes, milling machines, and even boring-milling machines—delivering high efficiency with exceptional stability. Take Huazhong Numerical Control’s 5-axis machining center, for example; it’s even integrated with AI chips, boosting machining efficiency by over 10% directly—who can resist that? 💥 What’s more, I think its biggest strengths are high precision and high repeatability, making it especially ideal for demanding fields like aircraft part manufacturing.

⚙️ High-Speed Machining Programming Strategies: Don’t Let Code Hold You Back

No matter how good the machine tool is, poor programming will render it useless! High-speed machining emphasizes "constant cutting load"—you must avoid sudden changes in tool direction and sharp turns, otherwise the tool may chip in an instant. It’s recommended to use spiral tool entry or arc transitions; for deep cavity machining, spiral plunge cutting, for instance, can reduce tool impact~ From my personal experience, the intelligent modules in modern CAM software can now automatically optimize toolpaths, making it easy even for beginners to get started!

📊 High-Speed Cutting Parameter Settings: Numbers Determine Success or Failure

Spindle speed, feed rate, and depth of cut—these three factors must work in harmony! High-speed machining typically uses high spindle speeds, fast feed rates, and small depths of cut. This not only reduces cutting force but also ensures precision. Let’s take an example 🌰: when machining aluminum alloy, we can crank the spindle speed up to several thousand revolutions per minute, but the depth of cut might only be a few tenths of a millimeter~ Oh, and don’t forget the cutting fluid! Without adequate cooling, the tool will overheat and become a disposable item in no time!

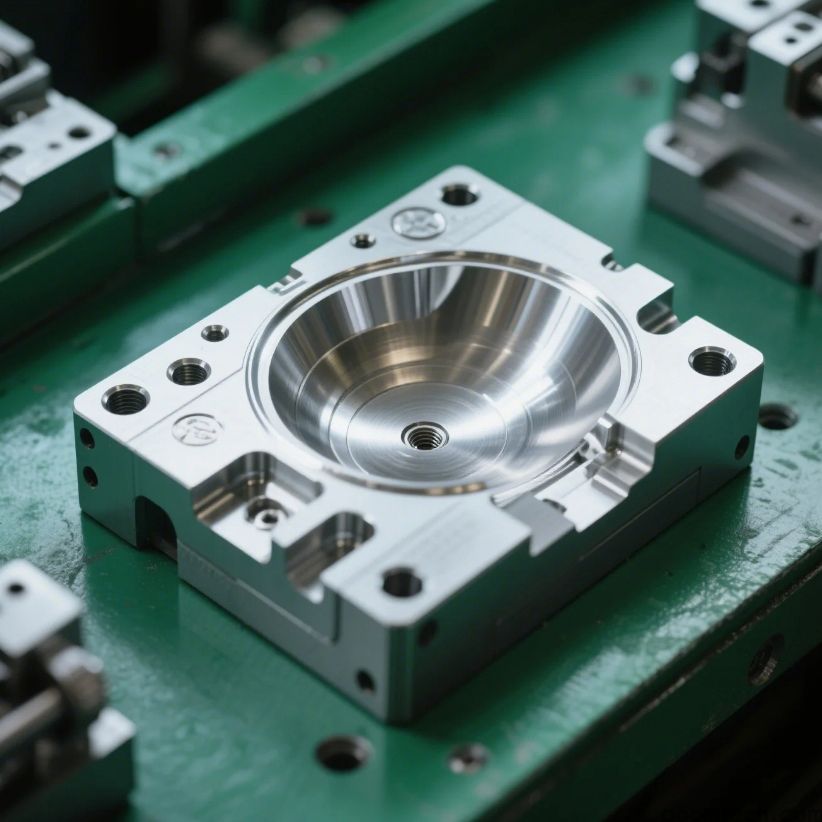

🛠️ High-Speed CNC Mold Machining: No Fear of Complex Curved Surfaces

Attention, friends from mold factories! High-speed CNC excels at machining complex profiles—like automotive molds or medical parts—and can even handle hard-to-reach corners flawlessly. 5-axis linkage is the star here, enabling multi-angle cutting in a single setup~ But I need to remind you: choosing the right material is crucial! Alloys like 6061 aluminum and 7075 aluminum are widely used; the latter has strength comparable to steel, taking durability to the next level 👍.

🚀 5-Axis High-Speed CNC Machining: Revealing High-End Applications

5-axis machining is the top-tier configuration for high-speed processing! It can control movement in five directions simultaneously, making it a breeze to machine 3D curved surfaces~ For example, impellers or engine components in the aerospace industry simply can’t do without it. However, the equipment is expensive and has high maintenance costs. I suggest small and medium-sized enterprises first assess their needs—if you frequently take orders for high-precision, irregular parts, the investment is definitely worthwhile; if you only produce simple parts, a 3-axis machine might be a more cost-effective choice 😉.

In short, high-speed CNC machining isn’t magic, but when used correctly, it truly doubles efficiency with half the effort! 💪 The key is to fully understand the equipment, programming, and materials—don’t blindly chase ultra-high parameters~ Finally, a sincere tip: regular machine maintenance and operator training are more practical than any "black technology"!

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C