What Is the Process of CNC Precision Machining? _ What Are the CNC Tips for Small Precision Parts?

Hello everyone! Today, I’m here to talk about CNC precision machining~ Many friends who are new to this industry always ask: “How exactly does this thing work? How can I avoid mistakes when machining small parts?” 😅 Don’t worry, let’s break it down step by step!

🔍 I. What Exactly Is the Process of CNC Precision Machining?

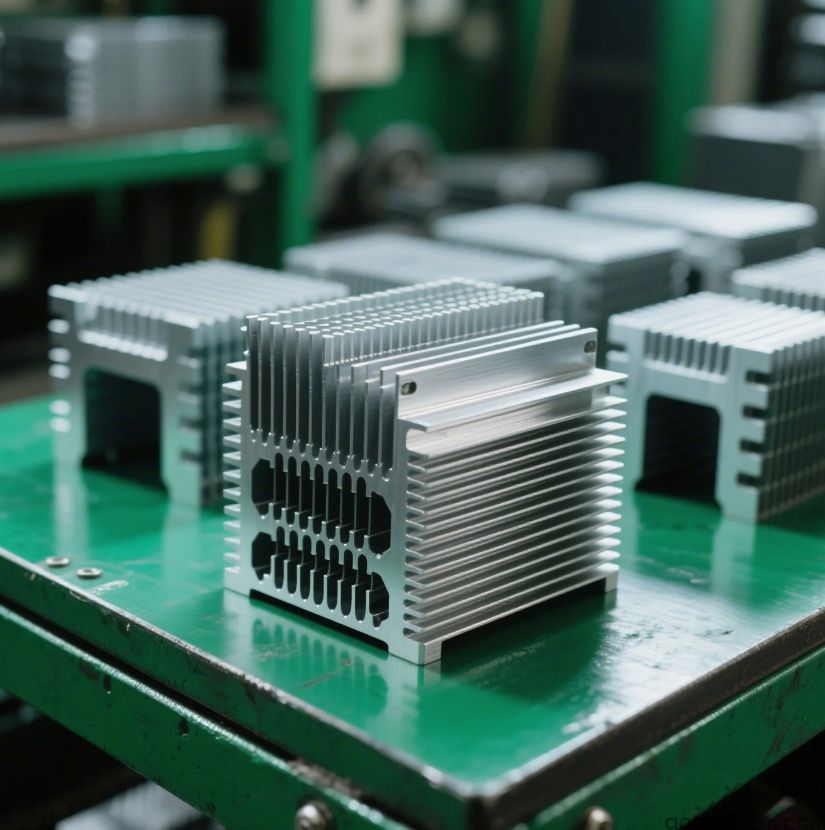

Simply put, CNC means using a computer to control machines for work! But precision machining has higher requirements—for example, for medical parts or optical components, a deviation of just 0.01mm may lead to scrapping! In my opinion, we must grasp the core process:

1. Design and Modeling: Use CAD to draw 3D diagrams, with key markings for tolerances and surface finish (e.g., ±0.01mm);

2. Programming and Coding: Convert to G-code via CAM. For small parts, it’s better to use area-priority toolpaths to save time;

3. Material Selection and Clamping: Aluminum or stainless steel are both usable, but small workpieces must use vacuum chucks to prevent vibration;

4. Tool Setting and Machining: Leave a 0.1mm allowance for rough cutting tools, and increase the spindle speed of finishing tools to over 12,000 rpm;

5. Inspection and Adjustment: Use micrometers and 3D coordinate measuring machines to check dimensions, and don’t forget to compensate for spark gaps!

A personal tip: Use micro-connecting tools more often during programming—this can boost efficiency by 30%! But don’t be greedy for speed and max out the spindle speed; newbies tend to break tool tips this way~

🛠️ II. Small Part Machining Tips: Details Determine Success!

Why do small parts always have issues? After years of experience, I’ve found that unstable clamping and wrong tool selection are the major pitfalls! For parts like phone SIM card trays or micro-gears, you can try these methods:

- Choose thin tools: Use φ0.5-2mm tungsten steel end mills and adopt layered cutting;

- Ensure sufficient cooling: Spray cutting fluid continuously, otherwise aluminum materials will deform immediately;

- Verify centering: Manually run the border after tool setting to prevent coordinate deviation!

👉 Let’s take an example: When machining eyeglass hinges, using a φ1mm tool with wire EDM (electrical discharge machining) can directly reduce the surface roughness to Ra 0.8!

📊 III. Comparison Table: Small Part vs. Large Part Machining

| Item | Small Parts | Large Parts |

|---------------------|---------------------------|---------------------------|

| Tool Selection | Thin tools (φ0.5-3mm) | Thick tools (φ10-20mm) |

| Clamping Method | Vacuum chuck + precision vice | Pressure plate + T-block |

| Precision Requirement | ±0.01mm (common) | ±0.02mm (acceptable) |

| Programming Strategy | Area priority, reduce empty tool paths | Layered cutting, maintain rigidity |

💡 IV. My Insight: A Guide for Newbies to Avoid Pitfalls!

After working in this field for so many years, I think newbies should pay attention to these points:

- Don’t blindly trust high spindle speeds: Test cut first before increasing speed; otherwise, tool life will drop sharply!

- Calibrate the machine regularly: Measure the Z-axis perpendicularity once a month—a tiny deviation of 0.01mm can ruin the entire batch of parts!

- Toolpath optimization is more important than machine quality: Even old machines can do precision work with good strategies~

Finally, a little reminder: Precision machining is like embroidery—patience will always pay off! If you encounter problems, feel free to leave a message, and we can figure them out together! ✨

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C