Common CNC Machining Types_Why Are 5-Axis CNC Milling Machines Suitable for Complex Surfaces?

Hey, are you new to CNC machining 🤔 and feel overwhelmed just hearing the term "5-axis (5-axis simultaneous operation)"? Don’t panic! Today, I’ll break it down in plain language to explain why this equipment is so amazing for handling complex surfaces!

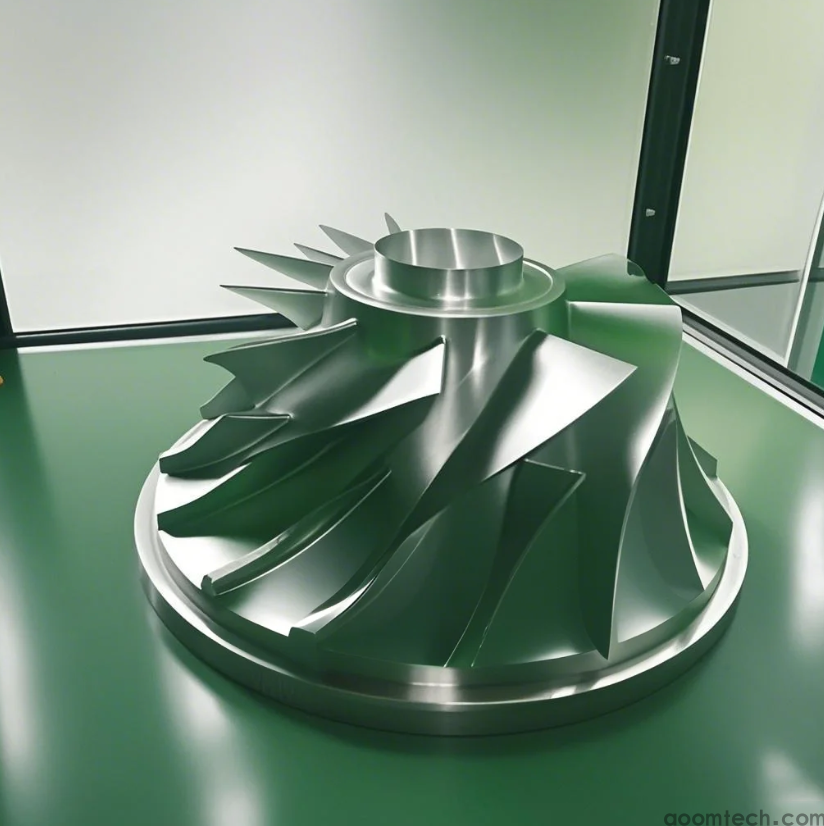

First, let’s talk about common CNC machining types—turning, milling, drilling, grinding, EDM (Electrical Discharge Machining)... But when it comes to irregular curved parts like aircraft blades or medical devices, ordinary 3-axis milling machines are totally out of their depth 😅! That’s when 5-axis simultaneous CNC milling machines step in. What makes them so powerful?

👉 The tool head can adjust angles! Ordinary machines can only cut straight up and down, but what about 5-axis ones? Their tool arms can rotate and tilt 360 degrees. For example, when machining turbine blades, the tool head can "bite" into the material along the curved surface, navigating all the twists and turns. A single cut can create a 3D shape, eliminating the hassle of repeated clamping.

👉 Unmatched precision! Dimensional deviations are the biggest nightmare for complex surfaces. 5-axis machines achieve simultaneous movement of the X/Y/Z linear axes plus two rotational axes (usually A and C axes), ensuring the tool always cuts perpendicularly to the workpiece surface. This not only results in a smooth, burr-free surface but also controls errors within ±0.01mm—that’s 1/7 the thickness of a human hair!

Let’s make a simple comparison between traditional 3-axis and 5-axis machines:

| Aspect | 3-Axis Milling Machine | 5-Axis Simultaneous Milling Machine |

|-----------------------|--------------------------------------|--------------------------------------|

| Surface Precision | Requires multiple machining passes; step marks tend to remain | One-time forming; smooth and uniform |

| Number of Clampings | At least 3-4 times | Done in 1 time |

| Suitable Parts | Flat surfaces, simple grooves | Impellers, human bone implants |

But some of you might ask: Why don’t most processing factories use 5-axis machines? Because they’re expensive, buddy! 💰 Not only does a 5-axis machine cost as much as 10 ordinary milling machines, but programming also requires CAM software to simulate tool paths—only technicians with at least 3 years of experience can operate it proficiently... That’s why they’re mostly used in aerospace and supercar industries right now.

My advice for beginners: If you want to enter the CNC field, first master 3-axis programming and operation, then advance to 5-axis machining. After all, complex surface machining is definitely a high-salary ticket in the future 🧱!

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C