Precision Auto Model CNC Machining, Custom Auto Model CNC Machining

Is your project stuck because you can't find a reliable way to make that perfect, detailed car model? You're not alone. Many enthusiasts and professionals face the same wall when standard parts just won't cut it. The secret weapon? CNC machining. It's the key to turning your digital designs into physical, high-precision auto models that capture every single curve and vent. Let's dive into how it works and why it might be the solution you've been searching for. 🚗✨

What Exactly is CNC Machining for Auto Models?

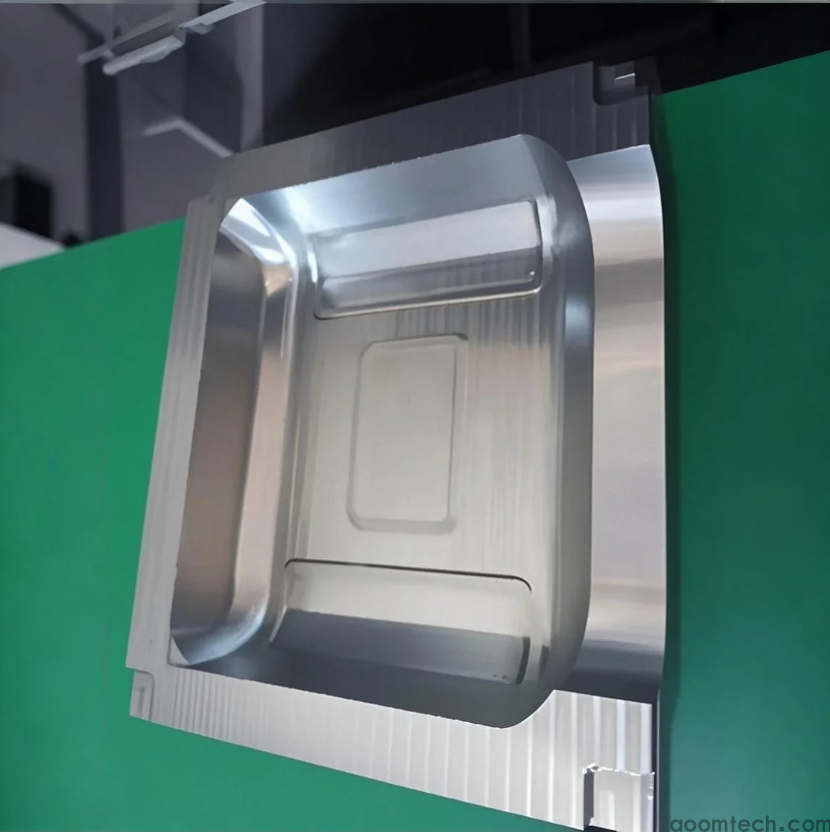

Think of CNC machining as a super-precise robotic sculptor. You start with a solid block of material, like aluminum or brass. A computer program (based on your 3D model) guides cutting tools to carve away material with incredible accuracy, layer by layer, until your car model emerges. It's fundamentally different from 3D printing, which adds material. CNC removes material, often resulting in stronger and more durable parts with a superior surface finish. For a car model, this means you can achieve those sharp body lines and intricate grille details that are hard to get elsewhere.

Why Choose CNC for Your Car Model Project?

So, why go through the trouble of CNC machining? The benefits are a game-changer for serious model making.

Unbeatable Precision & Detail: This is the biggest draw. CNC machines can hold tolerances within a hair's width. Every vent, emblem, and subtle contour on your model can be reproduced with stunning accuracy. This is what separates a toy-like model from a true collector's piece.

Material Freedom: Fancy an aluminum model that feels cold and heavy, like the real thing? Or perhaps a brass prototype? CNC machining works with a wide range of metals and engineering plastics, giving you the freedom to choose based on look, feel, and strength.

Strength and Durability: Because the parts are milled from a solid block, they have excellent structural integrity. They're less prone to warping or breaking compared to some other manufacturing methods.

What Does a "Custom" CNC Service Really Offer?

When we talk about "custom auto model CNC machining," what are we actually getting? It's not just about making a part; it's about bringing your unique vision to life.

From Your Design to Reality: A true custom service starts with your design file (like an STP or IGES file). They handle the technical translation into machine code and advise on design for manufacturability.

Scale and Complexity: Want a 1:8 scale model of a classic Ferrari? Or a highly complex model with moving parts? A custom shop can handle these specific requests, something off-the-shelf kits can't do.

Finishing Touches: The service often includes post-processing. This means they can polish the model to a mirror shine, bead-blast it for a matte finish, or even apply specific coatings or anodizing for color. I've found that the finishing is where the model truly comes to life, though the exact process for achieving a perfect chrome-like finish on complex geometries can be tricky and might depend on the material.

What Materials Work Best?

Picking the right material is crucial. It affects the look, weight, and even how well details can be captured.

Aluminum Alloys: This is the go-to for many. It's lightweight, strong, machines beautifully, and can be finished in many ways. It's perfect for the main body of the model.

Brass & Copper: These are great for a vintage or premium look. They are heavier and have a distinct feel. However, they can be softer and more expensive to machine.

Engineering Plastics (like ABS or Nylon): For certain internal parts or less demanding applications, these can be a cost-effective option. They're lightweight and can still hold good detail.

Having said that, the best choice isn't always straightforward. It often comes down to a trade-off between the desired aesthetic, budget, and the mechanical properties needed for the model. Sometimes, a combination of materials in one model works best.

Is CNC Machining Right for Your Project?

CNC machining is incredible, but it's not a magic wand for every single project. It truly shines when you need top-tier precision, material strength, and a professional finish. If you're making a one-off, highly detailed model for display or a small batch of prototypes, it's arguably the best method out there.

The main thing to consider is the cost for very low volumes. For a single model, the setup and programming time can make the per-part price higher than, say, 3D printing. But then again, the quality you get is on a different level. It's a balance between your quality requirements and your budget.

From my own experience, the leap in satisfaction from a 3D-printed model to a CNC-machined one is massive. The heft, the precision, the "realness" of it is just unparalleled. It's what makes the investment worthwhile for a centerpiece project.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C