Key Considerations for Precision CNC Mass Production: A Practical Guide

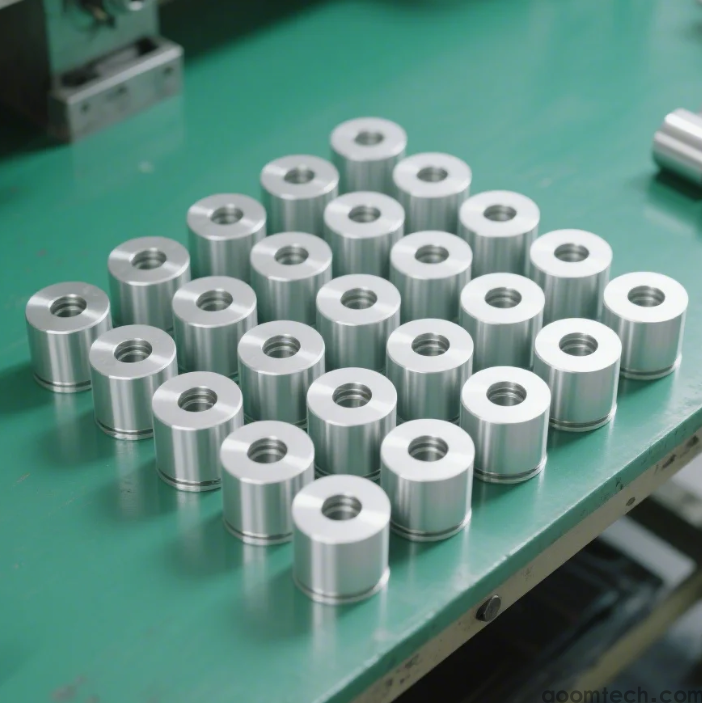

So, you're gearing up for a big order? 🚀 You've chosen CNC machining for its accuracy and repeatability, but the jump from prototyping to mass production can feel like a huge leap. Where do you even start to ensure everything runs smoothly and you get thousands of perfect parts, not thousands of expensive mistakes? This guide cuts through the noise and dives into the real-world considerations you need to know.

Wait, Isn't CNC Just for Prototypes?

That's a common thought! While CNC is fantastic for one-off models, it truly shines in mass production. The trick is planning. A flawless prototype doesn't automatically guarantee a smooth-running mass production. You have to think about things like tool wear over time, material consistency across batches, and setting up a workflow that doesn't just make one great part, but makes the ten-thousandth part just as great as the first.

Getting Your Design Production-Ready 🛠️

This is the first and most crucial step. A design that works for a prototype might be a nightmare to produce a thousand times.

Simplify Everything You Can: Look at every corner, every complex curve. Can a slightly simpler design achieve the same function but be machined faster? Even saving 30 seconds per part adds up to huge time savings.

Choose Materials Wisely: For mass production, you need a material that's not only strong enough but also readily available and consistent. A material that's hard to machine will wear out tools quickly, increasing costs and downtime. Sometimes, a more machinable material is the smarter choice for large volumes, even if it's not the "strongest" on paper.

Standardize Components: Are you using weird, custom-sized screws? See if you can switch to standard, off-the-shelf hardware. This makes assembly faster and sourcing replacements much easier.

Setting Up a Rock-Solid Quality Control System ✅

You can't check every single dimension on every single part. It's just not practical. So, how do you ensure consistency?

First-Article Inspection is Key: Before the production run truly begins, the first few parts off the line should be inspected with extreme care against all design specifications. This is your baseline.

Implement Smart Sampling: Instead of checking everything, establish a plan. For example, check every 50th part for critical dimensions. This gives you a good pulse on the process without slowing it down. The exact sampling rate, however, might depend on the part's complexity and the historical data from your machine, which is something we're still building a model for.

Monitor Tool Life: Tools don't last forever. Keep a log of how many parts each tool has made and change them before they fail. A worn-out tool doesn't always break suddenly; it often produces parts that are subtly out of spec, which is worse.

The Hidden Factor: Communication and Workflow

It's not all about the machines. A smooth flow of information is the glue that holds everything together.

Clear Documentation is a Must: Everyone, from the machine operator to the quality manager, needs access to the same, latest version of the drawings and specifications. A simple outdated document can ruin an entire batch.

Build a Relationship with Your Partner: If you're working with a machining shop, treat them as a partner. Talk to them early about your goals for cost-effectiveness and volume. They might have suggestions to optimize your design for production that you haven't considered. I've found that the best results come from these collaborative relationships, rather than just sending out a purchase order.

However, it's worth noting that even with perfect communication, unexpected material delays from suppliers can still throw a wrench in the tightest schedules. It's a complexity of modern supply chains that's hard to fully avoid.

Wrapping It Up: Think Beyond the Single Part

Successful mass production is a system. It connects smart design, vigilant quality checks, and clear human processes. By focusing on these practical considerations from the start, you shift from hoping for a good outcome to engineering one. The goal isn't just to make a lot of parts; it's to build a reliable process that delivers value, batch after batch. 🎯

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C