How Much Does Small-Batch CNC Machining for Custom Hardware Parts Cost? A Clear Price Breakdown

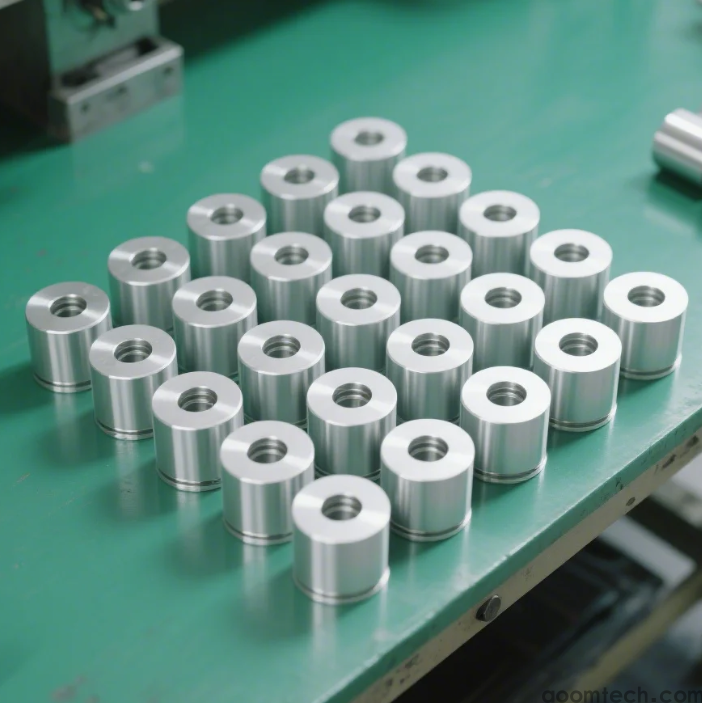

Feeling lost when you need just 50 or 100 custom metal parts, and every machine shop seems to quote a wildly different price? 😥 You're not alone. For procurement managers and engineers, getting a clear, upfront cost for small-batch, non-standard hardware CNC machining can feel like pulling teeth. This article cuts through the confusion and gives you a real-world look at the costs involved.

So, What's the Real Price Tag?

Let's get straight to the point. There's no single number, but for most small-batch custom hardware parts, you might be looking at a range of $50 to $500 per part, or even more for highly complex items. This wide range isn't a scam; it's because the final CNC machining cost is a puzzle made up of several key pieces.

The Big 4 Factors That Decide Your Final Bill

Think of pricing like a recipe. Change one ingredient, and the whole dish changes. Here’s what goes into the mix:

1. The Raw Material You Choose: This is your starting point. A block of aluminum is far cheaper than a block of titanium or stainless steel. It's not just the material cost per pound, but also how easy it is to cut. Harder materials wear out tools faster and take more machine time.

2. The Part's Design & Complexity: This is a huge one. A simple bracket is quick to make. But if your part has deep pockets, tiny holes, tight tolerances, or complex 3D curves, the machine has to work slower and make more passes. This directly eats into your budget by increasing the machine time.

3. The Quantity You Order (The Batch Size): This is where "small-batch" gets interesting. While the price per part is higher than mass production, the total cost is manageable. Setting up the machine (programming, fixing the material) has a fixed cost. Spreading that cost over 10 parts makes each part expensive. Spread it over 100, and the price per part drops significantly.

4. Post-Processing & Finishing: Do you need a smooth, polished look? Or a tough, coated surface? Basic milled finish is often included. But if you need anodizing, sandblasting, or plating, that's an extra step with its own labor and material costs.

A Peek at a Sample Scenario

Let's make this practical. Imagine you need a custom aluminum mounting plate.

Simple Design (2-3 hours machine time): Maybe around $80-$150 per part for 50 pieces.

Complex Design (5-8 hours machine time): The price could easily jump to $250-$400 per part for the same 50 pieces.

See how the complexity drives the time, and time drives the cost? This is why a simple photo or sketch can't get you an accurate quote.

My Personal Take on Getting the Best Deal

From my experience, chasing the lowest price per part can sometimes lead to headaches. A shop that quotes suspiciously low might be cutting corners on quality checks or using worn-out tools.

Instead, I focus on total value. A slightly higher quote from a shop that offers clear communication, detailed price breakdowns, and design-for-manufacturability advice is often cheaper in the long run. They can help you tweak a design to save hours of machine time, effectively paying for themselves. That said, it's always smart to get quotes from a few different suppliers to understand the market rate.

How to Actually Get an Accurate Quote?

You can't get a real number by just asking "how much?". To move from guessing to knowing, you need to provide a complete picture. The magic key is a good technical drawing (CAD file) that specifies:

- ✅ Material type

- ✅ Critical dimensions and tolerances

- ✅ Surface finish requirements

- ✅ The exact quantity you need

With this info, a machine shop can calculate the actual machine time and material needed. This transforms a vague question into a professional request for quotation.

Still have a specific project in mind but unsure about the cost? The best way to know for sure is to talk to an expert who can look at your designs. Reach out to our team today with your project details for a personalized, no-obligation quote! 👇

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C