Precision Hardware Parts CNC Mass Production: Your Ultimate Guide to Finding the Right Partner

Hey there! If you're a procurement manager or engineer sourcing for hardware parts CNC mass production, you know the struggle: finding a manufacturer that balances precision, cost, and reliability feels like searching for a needle in a haystack. You're not just buying parts; you're investing in your product's backbone. So, how do you cut through the noise and pick a partner that won't let you down? Let's dive in and unpack this step-by-step—no fluff, just straight talk from someone who's been in your shoes. 🔧

What Exactly Is Hardware Parts CNC Mass Production?

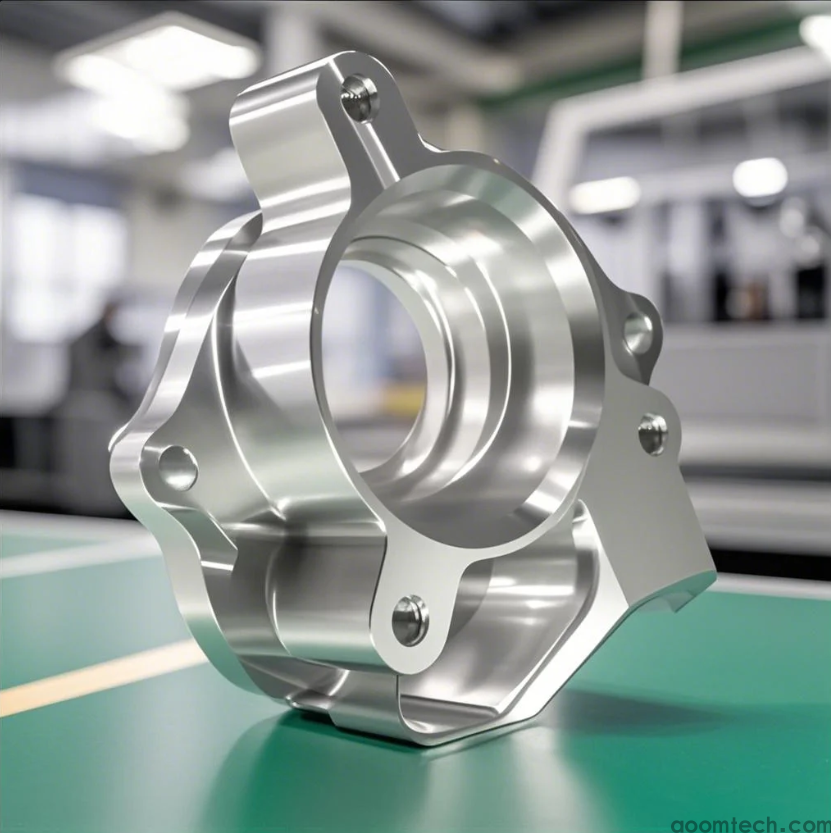

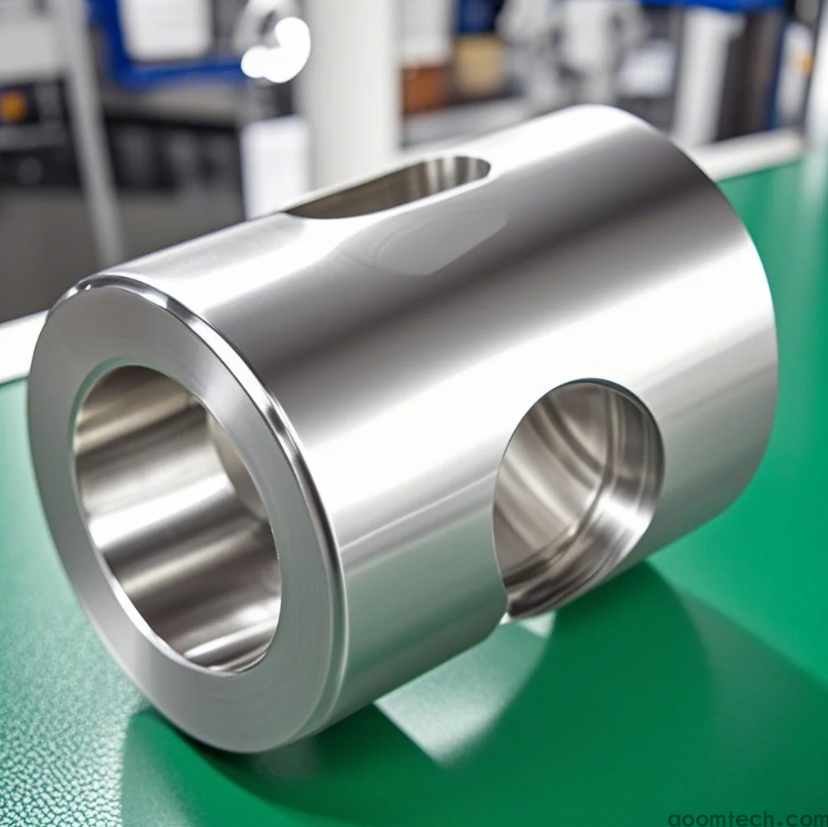

First things first: CNC mass production for hardware components involves using computer-controlled machines to churn out large volumes of parts—think screws, brackets, or custom fittings—with tight tolerances. It's like a high-tech workshop on steroids, where consistency is king. But here's the kicker: not all factories ace this. Some skimp on quality checks, while others lag on deadlines. I've seen projects derail because of "cheap" options that turned costly with reworks. So, while the tech is advanced, the human factor—like expertise and communication—can make or break your order.

Key Factors to Vet a CNC Production Manufacturer

When evaluating potential partners, don't just focus on price tags. Dig deeper into these aspects:

- Machine Capability & Capacity: Can they handle your volume without bottlenecks? Look for multi-axis CNC setups that reduce errors.

- Material Sourcing & Quality Control: Do they test raw materials and implement stage-wise inspections? A slip here might lead to part failures.

- Lead Time & Communication: Are they proactive with updates? Delays often stem from poor coordination, not technical issues.

From my experience, visiting the facility (or a virtual tour) reveals a lot. One client once avoided a disaster by spotting outdated machines during a visit—despite the supplier's "state-of-the-art" claims. So, trust but verify! 👀

Common Pitfalls in Hardware CNC Batch Orders (And How to Dodge Them)

Let's be real: mistakes happen, but learning from others saves time and money. Here are frequent hiccups:

- Overlooking Tolerance Specifications: A tiny deviation in dimensions can cause assembly nightmares. Always double-check blueprints with the manufacturer.

- Ignoring Surface Finish Requirements: Parts might look fine but corrode quickly if finishing isn't suited to their environment.

- Choosing Based Solely on Low Quotes: Cheap often means corners cut. One engineer I worked with regretted picking the lowest bidder after receiving parts with inconsistent threading.

That said, it's not all doom and gloom. Many issues are avoidable with clear documentation and samples. Perhaps this hints that a collaborative approach beats a transactional one.

Why On-Time Delivery Matters More Than You Think

In mass production, delays ripple through your supply chain, stalling entire projects. I've noticed that manufacturers with integrated logistics—like in-house packaging and shipping coordination—tend to deliver smoother. But remember, "fast" shouldn't compromise quality. One supplier I recommend always allocates buffer time for unexpected snags, which saved a client during a material shortage. So, ask about their contingency plans—it's a telltale sign of reliability. ⏱️

Next Steps: How to Initiate a Successful Partnership

Ready to move forward? Start by sharing your design files for a feasibility review. Reputable manufacturers will suggest optimizations for cost or durability. Then, request a small batch prototype to test everything from material strength to fit. If that checks out, scale up with clear milestones. And hey, if you're unsure, just reach out to our team for a tailored consultation—we're here to help you navigate this smoothly! 💬

Insight nugget: Based on industry chatter, suppliers who engage early in the design phase reduce revision rates by up to 30%. It's those hidden efficiencies that separate okay partners from great ones.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C