Looking for Professional Small-Batch CNC Aluminum Parts? Your Search Ends Here.

Stuck in a cycle of getting quotes from big factories that just aren't interested in your smaller project? 😥 You have a brilliant design, a prototype that needs testing, or a limited production run, but it feels like no one wants your business. This is a common headache. But what if you could find a machining partner that actually welcomes small orders and treats them with the same care as large ones? Let's break down why "professional small-batch CNC aluminum machining" might be the exact solution you're searching for.

What Exactly is "Small-Batch" CNC Machining, Anyway?

Simply put, small-batch machining is all about producing a limited quantity of parts—anywhere from a single prototype to a few hundred pieces. It's not about massive volumes. The core idea here is flexibility and accessibility. While big manufacturers are set up for long, uninterrupted production, a shop focusing on small batches is built to handle your project quickly and efficiently, without the high costs and long wait times.

Why Would I Even Need a Specialist for Small Batches?

Great question! You could try your luck with any machine shop, but a specialist makes a world of difference. Think of it like this: a chef in a busy hotel kitchen might struggle to give attention to a single, custom meal, while a private chef thrives on it.

Here’s the real benefit:

- 💰 Cost-Effectiveness: Lower upfront costs since you're not paying for material and machine time for thousands of parts.

- 🚀 Speed & Agility: Faster turnaround times from design to finished parts in your hands.

- 🔧 Iterate and Improve: Perfect for testing a design, making adjustments, and then ordering a revised version without being stuck with obsolete inventory.

However, it's worth mentioning that some folks worry about quality consistency in smaller runs. A true professional shop, though, has processes in place to ensure every single part, from the first to the last, meets your specs.

How Do I Know If a Shop is Truly "Professional"?

This is where many people get tripped up. "Professional" is more than just a word on a website. You need to look for signs of real expertise.

My go-to checklist includes:

- They talk openly about their quality control process. How do they check the parts?

- They have experience with your specific type of aluminum or similar projects.

- Their communication is clear and prompt from the very first inquiry.

I often see shops that say they can do it all, but their portfolio tells a different story. A shop that regularly handles complex aluminum components for various industries is usually a safer bet than a general-purpose one. This might suggest they have the right mindset and equipment.

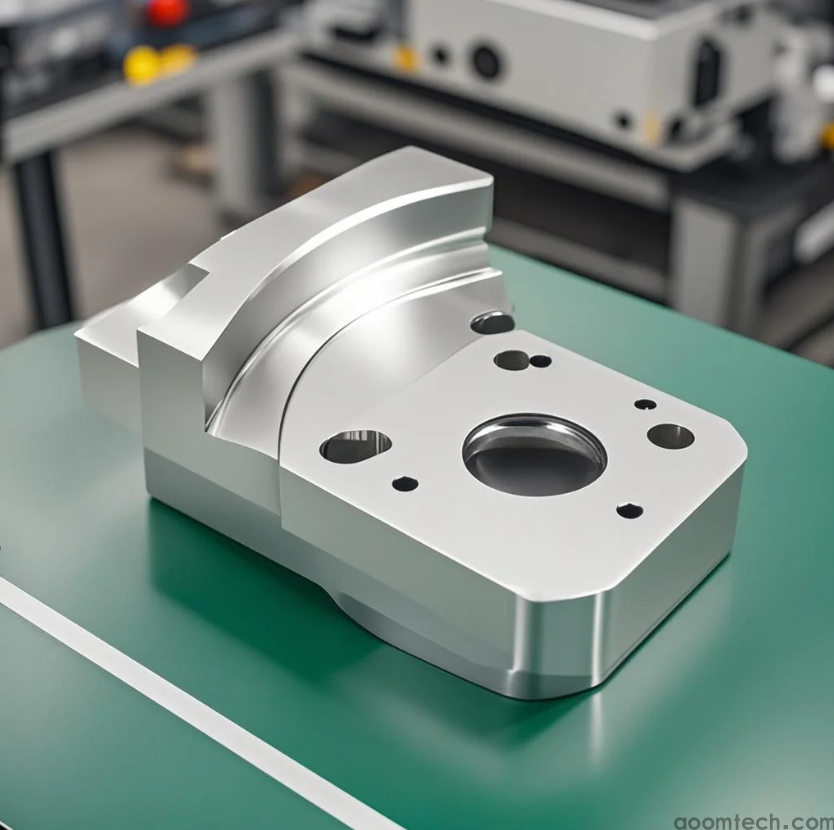

What About the "CNC Aluminum Parts" Themselves?

Let's talk about the material for a second. Aluminum is popular for a reason—it's strong but light, and it's generally easy to machine. But not all aluminum is the same. A good machining partner should be able to guide you on the best aluminum grade for your part's job. Will it need to handle stress? Be exposed to the elements? The right choice here impacts everything.

The beauty of CNC machining for these parts is the incredible precision and repeatability. You get parts that are virtually identical, which is crucial whether you're assembling a product or just need reliable consistency.

Okay, I'm Convinced. What's the Next Step?

If you're tired of hitting dead ends with suppliers who don't value your smaller-scale needs, it's time to try a different approach. The goal is to find a partner, not just a vendor.

You don't have to compromise on quality or service just because your order isn't huge. There are specialists who are ready to listen to your specific requirements and deliver the high-quality, precision aluminum parts you need to move your project forward.

Why not start a conversation with a team that builds its service around this exact need? 👉 Reach out to our online service team now for a direct quote and see how we handle small batches with big care.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C