What is High Precision CNC Mold Processing and How Does It Work?

Ever found yourself staring at a perfectly shaped plastic part and wondering, "How do they make this so precise?" 🤔 Or maybe you're a procurement manager struggling to find a supplier who can consistently deliver molds that fit like a glove? If you've been burned by suppliers promising "high precision" but delivering mediocre results, you're not alone. Let's break down what high precision CNC mold processing really means and why it matters for your business.

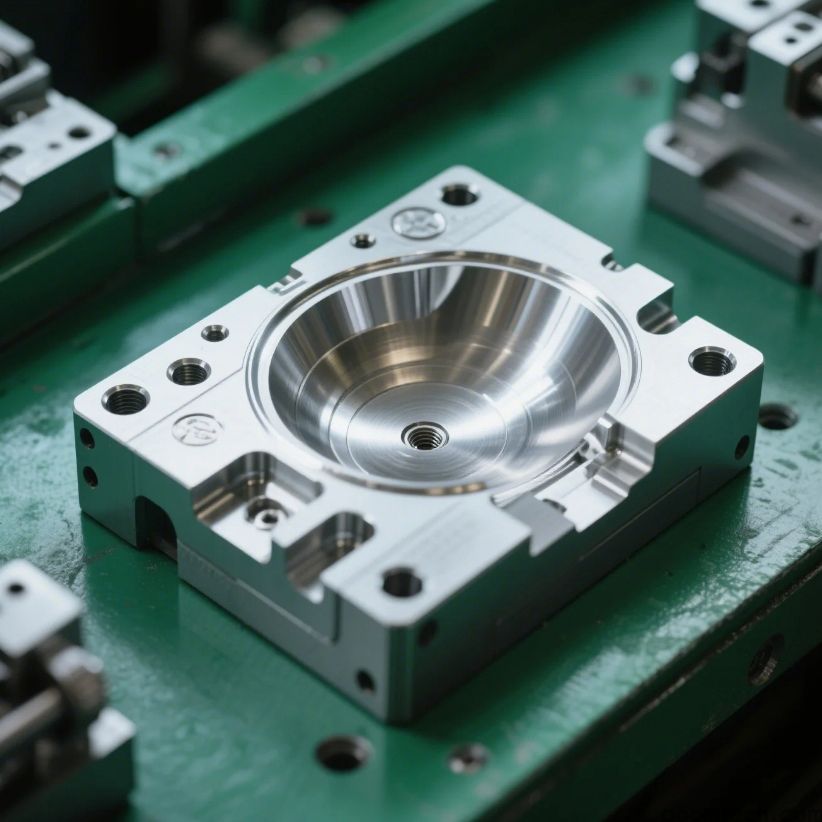

What Exactly is High Precision CNC Mold Processing?

Simply put, it's like using a super-smart carving machine that can create molds with incredible accuracy. Think of it as the difference between cutting paper with scissors versus using a laser cutter - both get the job done, but one gives you that perfect edge every time.

I've seen many factories claim they do "precision machining," but the real test comes when you measure the final product. True high precision means every cut, every curve, every tiny detail matches the digital design exactly. It's not just about having fancy machines - it's about how you use them.

Why Should You Care About Mold Precision?

• Fewer rejected parts - When molds are precise, your production line runs smoother with less waste

• Longer mold life - Properly made molds just last longer, saving you money down the road

• Better product quality - This might seem obvious, but precise molds mean consistent, high-quality outputs

Though I should mention - higher precision usually comes with a higher price tag. But in my experience, paying a bit more upfront often saves you from headaches (and costs) later when dealing with production issues.

How Do Manufacturers Achieve This Precision?

It's not just about having good equipment (though that helps). The real magic happens in three areas:

1. Machine calibration - Regular check-ups ensure everything's running perfectly

2. Operator skill - Even the best machines need skilled hands

3. Quality control - Constant checking at every step

I've visited workshops where they had all the latest gear but still produced mediocre work because they skipped on proper maintenance. The machines were basically running while slightly "drunk" - not ideal for precision work!

Common Challenges in High Precision Mold Making

• Temperature changes affecting measurements

• Material behaving unexpectedly

• Tool wear changing cutting accuracy

Here's something I've noticed - many shops focus only on the machine's capabilities while ignoring environmental factors. The room temperature, humidity, even how the machine is positioned can affect the final precision. It's like trying to take a perfect photo with a shaky hand - you need stability everywhere.

What Makes Some Shops Better at Precision Work?

From what I've seen, the best shops have this interesting mix of high-tech equipment and old-school craftsmanship. They use advanced CNC systems but also have experienced workers who can "feel" when something's not right.

Their quality control processes are usually more thorough too. Instead of just checking the final product, they verify measurements at multiple stages. This approach might suggest they catch errors early, preventing bigger issues later.

Looking for reliable high precision CNC mold processing? Our technical team can help you navigate these complexities - just reach out to our online consultants for personalized guidance. 👨💻

Sometimes the smallest details in mold making create the biggest differences in your final product. I've seen cases where a tiny adjustment of .01mm completely transformed part quality - proof that in precision work, every micron truly counts.

How is the price calculated fo

How is the price calculated fo

How Does a High-Precision CNC

How Does a High-Precision CNC

What Factors Affect CNC Machin

What Factors Affect CNC Machin

How to Choose a Supplier for C

How to Choose a Supplier for C