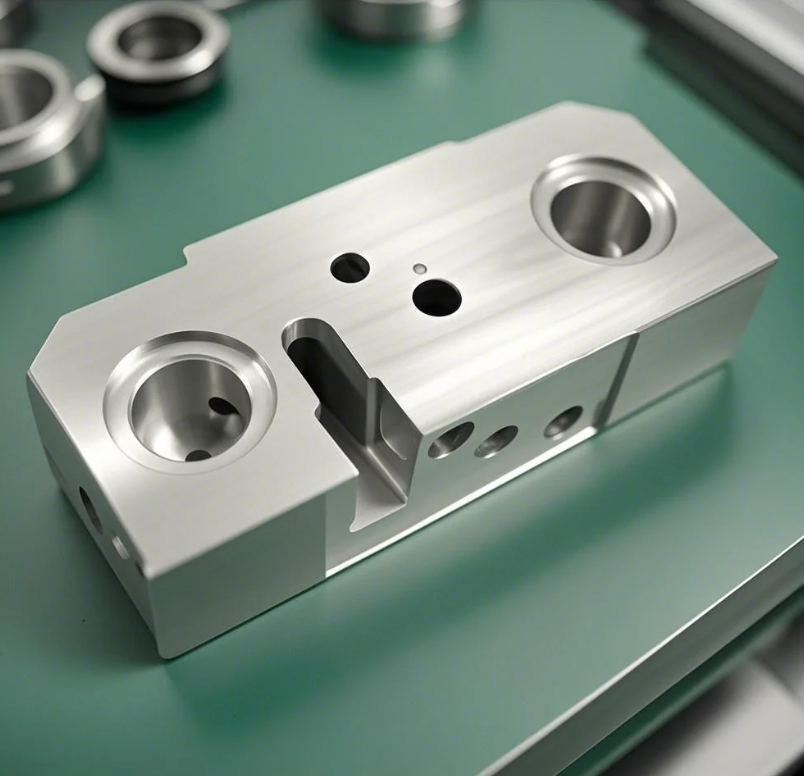

CNC Product Processing Quotation

When sourcing CNC machining services, understanding cost factors is critical for procurement managers and engineers to make informed decisions. AOOM Technology, as a precision machining specialist, breaks down the key elements that determine CNC Product Processing Quotation to help you optimize budgets without compromising quality.

Key Factors Affecting CNC Machining Costs

1. Material Selection: Aerospace aluminum (6061/7075) costs 20-35% less than titanium but requires different tooling strategies.

2. Part Complexity: A 5-axis milled component with ±.01mm tolerance may cost 3-5X more than basic turned parts.

3. Order Volume: Batch production of 500+ units typically reduces per-unit cost by 40-60% through optimized tool paths.

AOOM's Transparent Pricing Structure

Our CNC machining quotes include:

- Machine time (calculated per 15-minute increments)

- Material certification (ISO 9001 compliant)

- Post-processing (anodizing, polishing, etc.)

- Quality inspection reports (CMM data available)

Cost-Saving Strategies We Recommend

1. Design for Manufacturability: Our engineers provide free DFM analysis to eliminate unnecessary machining steps.

2. Material Optimization: We suggest alternative alloys that meet specs but reduce raw material costs by up to 30%.

3. Standardized Tooling: Utilizing our in-house tool library avoids custom tooling charges.

Why AOOM Delivers Competitive Pricing

- 18 Swiss-type CNC lathes with bar feeders for continuous production

- On-site material warehouse with bulk purchase discounts

- Proprietary CAM software reduces programming time by 25%

- ISO 13485 certified for medical-grade precision at industrial rates

Request a custom quote with your 3D files for precise pricing tailored to your project requirements.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F