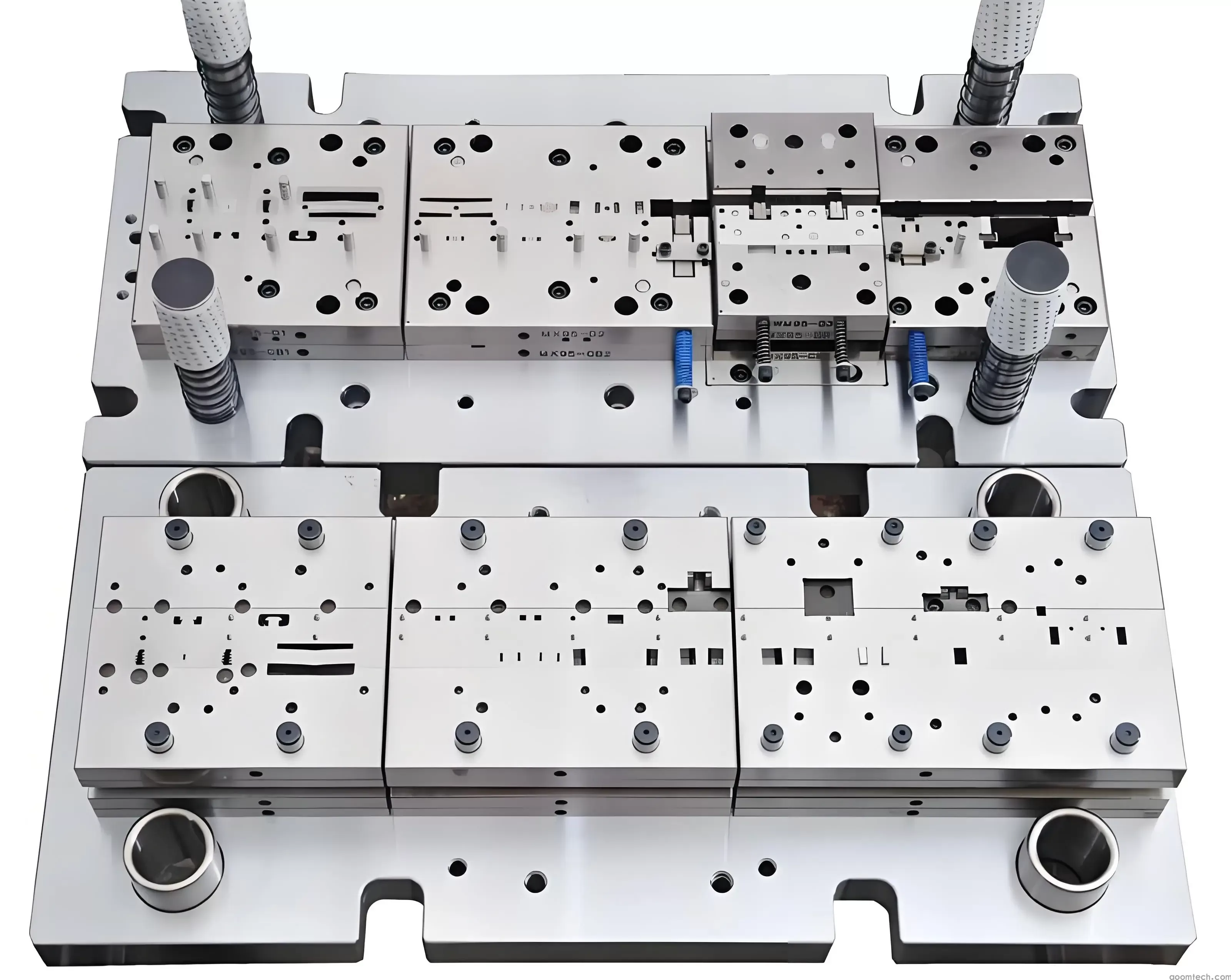

CNC Mold Machining Process Flow

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-precision mold manufacturing solutions. This article will break down the complete CNC mold machining process flow, addressing key concerns for procurement managers and engineers seeking reliable manufacturing partners.

1. Design Analysis & CAD Modeling

The process begins with thorough design analysis using CAD software. Our engineers evaluate mold functionality, material selection, and tolerance requirements (typically ±.01mm for precision molds). AOOM's team utilizes Siemens NX and SolidWorks to create optimized 3D models that meet DFM (Design for Manufacturing) principles.

2. Material Preparation

We source premium mold steels (P20, H13, S136) or aluminum alloys (7075-T6) based on application requirements. Materials undergo ultrasonic testing to ensure internal integrity before machining. Our ISO 9001-certified warehouse maintains traceability for all raw materials.

3. CNC Programming

Using CAM software like Mastercam, our programmers develop efficient toolpaths considering:

- Optimal cutting parameters (speed/feed/depth)

- Tool selection (carbide end mills, ball nose cutters)

- Coolant strategy (flood cooling or MQL)

4. Precision Machining Operations

Our 5-axis CNC machines (Mazak, DMG Mori) execute the process with sub-micron accuracy:

- Roughing: Removes 80-90% material with high-efficiency milling

- Semi-finishing: Achieves near-net shape

- Finishing: Delivers surface finishes up to Ra .2μm

- EDM: For complex geometries and hardened steels

5. Quality Control

Every mold undergoes rigorous inspection using:

- CMM (Coordinate Measuring Machines)

- Optical comparators

- Surface roughness testers

6. Post-Processing & Assembly

The final stage includes:

- Polishing (hand or robotic)

- Heat treatment (when required)

- Functional testing with trial shots

At AOOM Technology, we combine advanced equipment with 15+ years of mold-making expertise to deliver CNC machined molds with 99.8% first-pass success rate. Our end-to-end process control ensures consistent quality for injection molds, die casting molds, and stamping dies.

Visit aoomtech.com to request a free DFM analysis or project quotation today.

CNC Machining Parts Customizat

CNC Machining Parts Customizat

Recommendation for CNC Precisi

Recommendation for CNC Precisi

CNC Precision Machining Custom

CNC Precision Machining Custom

CNC Machining Metal Lighting F

CNC Machining Metal Lighting F