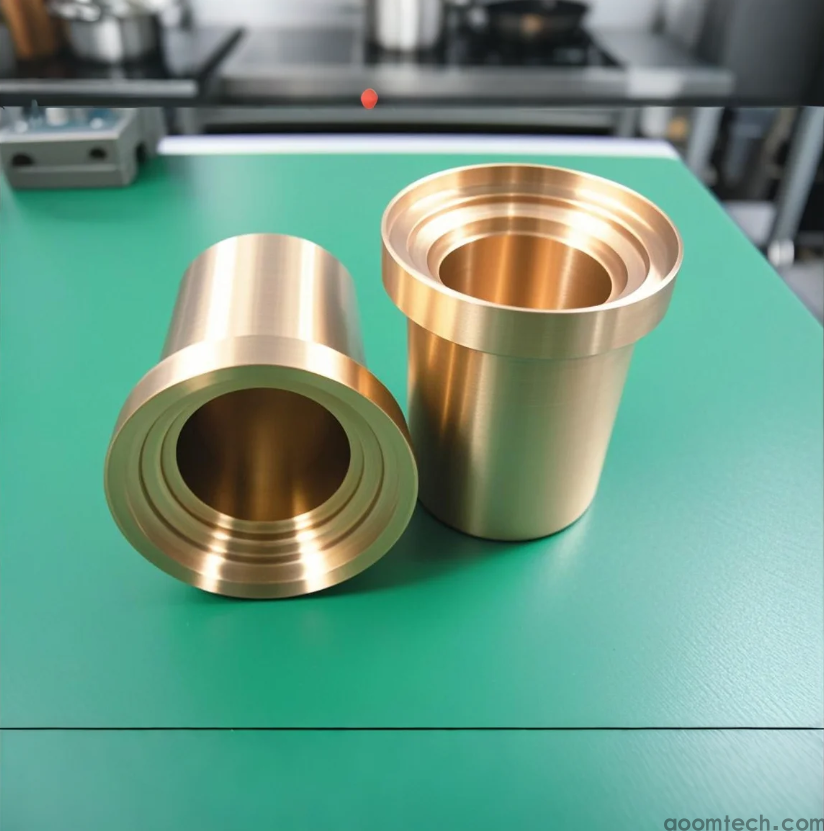

CNC Machining Brass Parts: Process and Applications

Brass is a popular material in manufacturing due to its excellent machinability, corrosion resistance, and aesthetic appeal. CNC machining brass parts offers high precision and repeatability, making it ideal for industries like automotive, electronics, and plumbing. This article explores the process, advantages, and applications of CNC-machined brass components.

Why Choose Brass for CNC Machining?

Brass is a copper-zinc alloy known for its durability and versatility. Its properties include:

- Superior machinability (free-cutting brass alloys can achieve speeds up to 1,000 SFM)

- Natural corrosion resistance

- Excellent electrical and thermal conductivity

- Attractive gold-like appearance

These characteristics make brass particularly suitable for CNC machining complex geometries with tight tolerances (±.005 inches or better).

The CNC Machining Process for Brass Parts

At AOOM, we follow a rigorous process for CNC machining brass parts:

- Material Selection: Choosing the right brass alloy (C36000 for general machining, C46400 for marine applications)

- CAD Design: Creating 3D models with DFM (Design for Manufacturing) principles

- Toolpath Programming: Optimizing cutting paths for efficiency and surface finish

- Machining Operations: Utilizing 3/4/5-axis CNC mills and lathes

- Quality Inspection: Verifying dimensions with CMM and surface roughness testers

Applications of CNC Machined Brass Components

Our CNC brass parts serve critical functions across industries:

- Plumbing: Valve bodies, fittings, and faucet components

- Electronics: Connectors, terminals, and RF shielding

- Automotive: Fuel system components and decorative trim

- Musical Instruments: Precision valves and mouthpieces

AOOM's Capabilities in Brass CNC Machining

As a trusted CNC machining service provider, AOOM offers:

- Advanced Swiss-type and multi-axis CNC machines

- Material certifications and full traceability

- Secondary operations (deburring, polishing, plating)

- Prototype to high-volume production (50-50,000+ units)

Our expertise ensures your brass parts meet the strictest quality standards while maintaining cost-efficiency. Contact us today to discuss your project requirements.