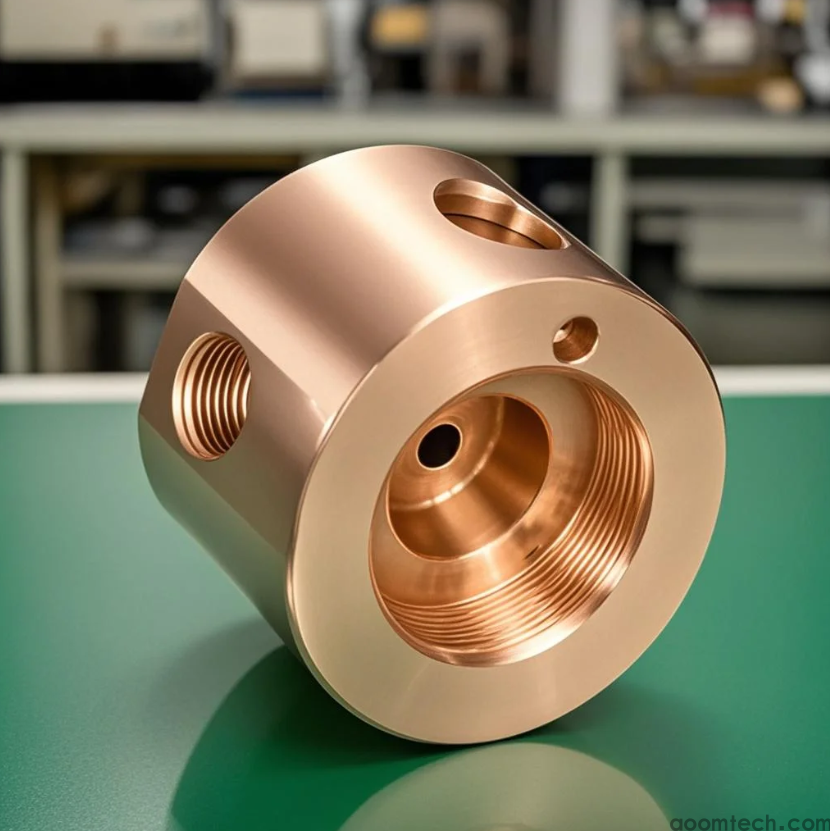

CNC Machining Brass Products

Brass, a versatile copper-zinc alloy, is widely used in industries ranging from electronics to plumbing due to its excellent machinability, corrosion resistance, and aesthetic appeal. At AOOM Technologies, we specialize in CNC machining brass products with micron-level precision, delivering components that meet the strictest industry standards.

Why Choose CNC Machining for Brass Components?

CNC technology offers unparalleled advantages for brass machining:

- High Precision: Achieve tolerances as tight as ±.01mm for critical dimensions

- Complex Geometries: Produce intricate shapes impossible with conventional methods

- Superior Surface Finish: Achieve Ra .8μm or better without secondary processing

- Batch Consistency: Maintain identical specifications across mass production runs

Our Brass CNC Machining Capabilities

AOOM Technologies' advanced CNC machining center handles all brass alloys (C36000, C26000, etc.) with specialized tooling:

- 5-axis simultaneous machining for complex contours

- Swiss-type CNC lathes for precision turned parts

- High-speed milling (up to 20,000 RPM) for fine details

- In-process quality control with CMM verification

Key Applications of CNC Machined Brass Parts

Our CNC machined brass products serve critical functions across industries:

- Electronics: Connectors, terminals, and RF shielding components

- Fluid Systems: Valve bodies, fittings, and hydraulic components

- Automotive: Fuel system parts, bushings, and decorative trim

- Musical Instruments: Precision valves and mechanical components

Why Partner with AOOM Technologies?

As an ISO 9001-certified manufacturer, we combine cutting-edge CNC technology with decades of brass machining expertise:

- Material traceability from certified suppliers

- DFM analysis to optimize your design for manufacturability

- Just-in-time delivery with kanban inventory systems

- Comprehensive post-processing options (plating, polishing, laser marking)

Contact our engineering team at AOOM Technologies to discuss your brass CNC machining project requirements and receive a free DFM analysis.