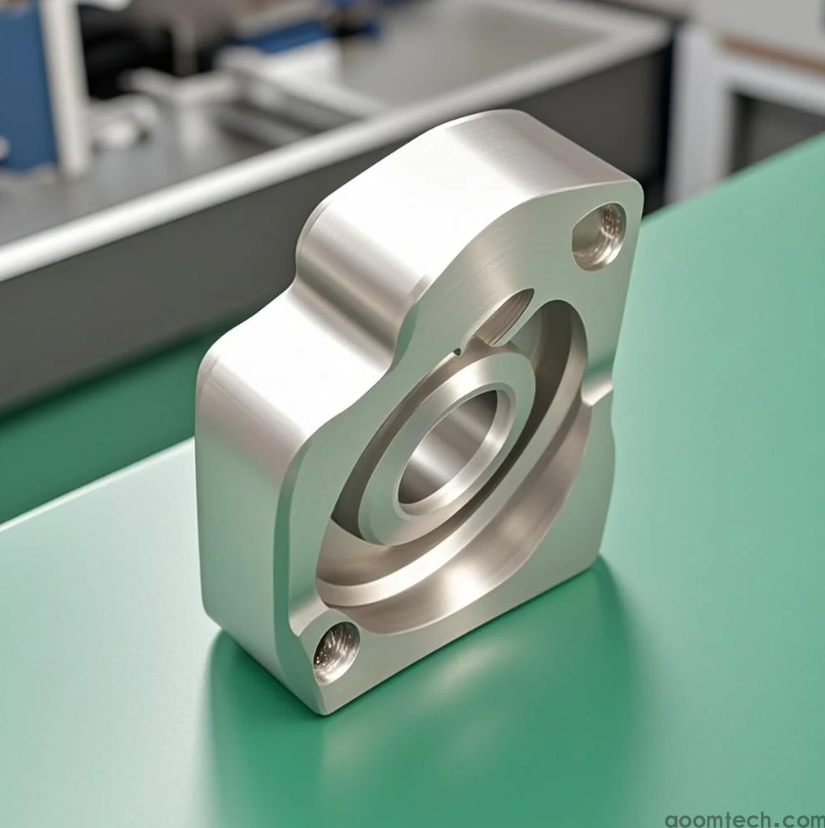

CNC Machining Ship Engine Parts

In the marine industry, precision and durability are non-negotiable for ship engine components. CNC machining has become the gold standard for manufacturing these critical parts, ensuring optimal performance even in harsh oceanic environments.

Why Choose CNC Machining for Marine Engine Components?

Ship engines demand components that can withstand extreme pressures, corrosion, and continuous operation. CNC machining offers:

- ±.005mm tolerance for perfect fit and function

- Superior material integrity compared to casting

- Complex geometries achievable in single setups

- Repeatable quality for fleet maintenance

Key Materials for Marine Engine Parts

At AOOM, we specialize in machining:

- Marine-grade aluminum alloys (5083, 6061-T6)

- Stainless steel (316L, 2205 duplex)

- Bronze and nickel-aluminum bronze alloys

- High-strength titanium components

Our CNC Capabilities for Marine Applications

Our CNC machining center features:

- 5-axis simultaneous machining for complex contours

- High-pressure coolant systems for tough materials

- In-process inspection with CMM integration

- Saltwater corrosion testing protocols

With AOOM's CNC expertise, shipbuilders and maintenance teams receive engine components that meet ABS, DNV, and Lloyd's Register standards. Our technical team understands the unique demands of marine propulsion systems and delivers solutions that outperform conventional manufacturing methods.

Write your message here and send it to us