CNC Machining Copper Parts: Precision, Process, and Applications

In modern manufacturing, CNC machining copper parts has become a critical process for industries requiring high electrical/thermal conductivity and precision. As a leading CNC machining service provider, AOOM Technology delivers exceptional copper components with tight tolerances (±.01mm) and superior surface finishes (up to Ra .4μm).

Why Choose CNC for Copper Parts?

Copper's unique properties – 100% IACS conductivity, excellent ductility, and antimicrobial characteristics – make it ideal for electrical components, heat exchangers, and medical devices. However, its softness and gummy nature require specialized CNC machining techniques that AOOM has mastered through years of R&D.

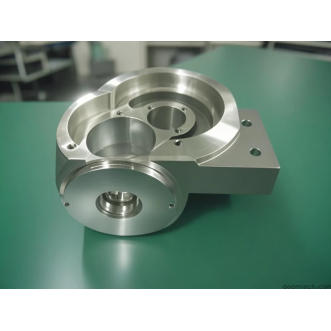

Our Copper CNC Machining Capabilities

At AOOM, we employ:

- 5-axis CNC mills for complex geometries in C10100/C11000 alloys

- Swiss-type lathes for high-volume precision turned components

- Micro-machining (down to .1mm features) for electronics applications

- Post-processing including electropolishing and passivation

Industry-Specific Solutions

We serve:

- Electronics: Busbars, connectors (meeting IPC-6012 standards)

- Automotive: EV battery components with 99.9% purity copper

- Medical: Antimicrobial touch surfaces (ISO 13485 compliant)

With ISO 9001-certified processes and 24/7 production monitoring, AOOM guarantees copper parts with ≤.5% porosity and 100% conductivity verification. Our engineers optimize tool paths to prevent work hardening while achieving ±.005" positional accuracy.