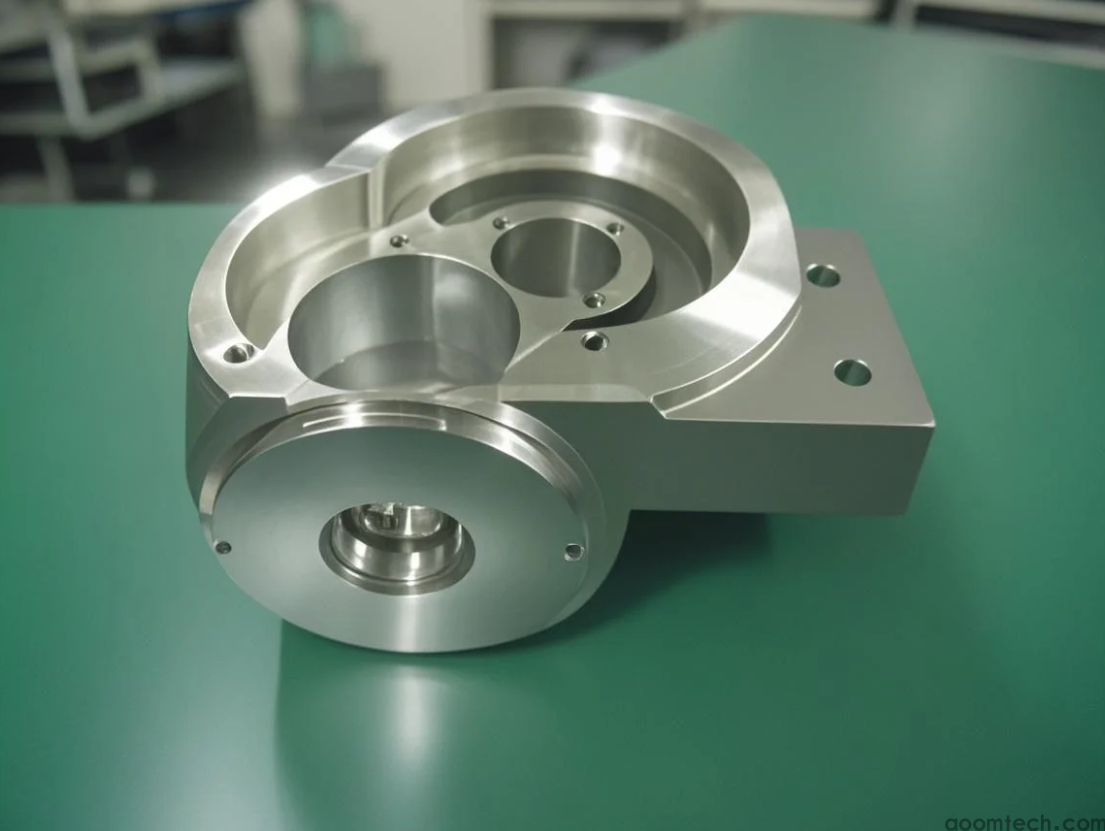

Ship Parts CNC Machining Process

As a leading ship parts CNC machining service provider, AOOM Technology specializes in manufacturing high-precision marine components for various vessel types. Our advanced CNC capabilities ensure the production of durable, corrosion-resistant parts that meet stringent maritime industry standards.

Understanding Ship Parts CNC Machining

Ship parts CNC machining involves the computer-controlled manufacturing of marine components with extreme precision. This process is crucial for creating propellers, shafts, valve bodies, pump components, and other critical marine hardware that must withstand harsh ocean environments.

Key Advantages of Our CNC Machining for Marine Applications

AOOM Technology offers several benefits for ship parts CNC machining:

Material expertise in marine-grade aluminum, stainless steel, bronze, and special alloys

Tight tolerances (±.005mm) for perfect fit and function

Advanced 5-axis machining for complex geometries

Saltwater corrosion resistance solutions

Full compliance with international marine standards (DNV, ABS, LR)

Our CNC Machining Process for Marine Components

Our comprehensive ship parts CNC machining process includes:

Material selection and certification verification

CAD/CAM programming optimized for marine applications

Precision machining with vibration dampening technology

Surface treatment for enhanced corrosion protection

Rigorous quality inspection including CMM verification

Why Choose AOOM Technology for Marine CNC Machining?

With years of experience serving the marine industry, AOOM Technology stands out for our:

Specialized knowledge of marine engineering requirements

Quick turnaround for emergency repairs and replacements

Competitive pricing for bulk orders

Complete documentation package including material certificates

Global shipping capabilities to major ports worldwide

For reliable, high-quality ship parts manufactured with precision CNC technology, contact AOOM Technology at www.aoomtech.com to discuss your marine component requirements.