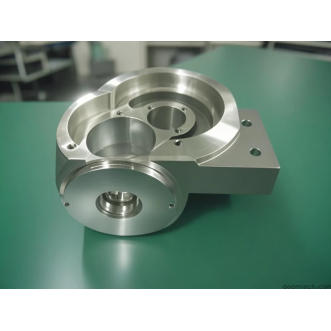

Product Parts CNC Machining Process

As a professional CNC machining service provider, AOOM Technologies specializes in manufacturing high-precision product parts for various industries. This article will explain the complete workflow, technical advantages, and quality control measures of our CNC machining services.

Understanding Product Parts CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses pre-programmed computer software to control machine tools. For product parts manufacturing, this technology enables us to produce complex geometries with tight tolerances (up to ±.005mm) and excellent surface finishes.

Our CNC Machining Capabilities

AOOM Technologies operates advanced 3-axis, 4-axis, and 5-axis CNC machines capable of handling:

Metal parts (aluminum, steel, titanium, brass)

Plastic components (PEEK, Delrin, PTFE)

Prototypes and mass production

Complex geometries and thin-walled structures

Quality Assurance Process

We implement strict quality control measures at every production stage:

Material inspection (certificate verification)

In-process dimensional checks

Final inspection with CMM (Coordinate Measuring Machine)

Surface roughness testing

Why Choose AOOM Technologies?

Our advantages in product parts CNC machining include:

15+ years of machining experience

ISO 9001:2015 certified facility

Fast turnaround (as quick as 24 hours for prototypes)

Competitive pricing for bulk orders

DFM (Design for Manufacturing) support

For your next project requiring precision CNC machined parts, visit our website at www.aoomtech.com or contact our engineering team for a free quotation and technical consultation.