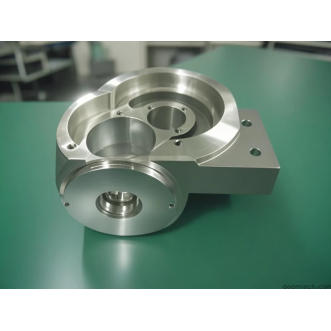

CNC Copper Parts Processing: Precision Machining for High-Performance Applications

As a leading CNC copper parts processing specialist, AOOM Technology delivers exceptional machining solutions for industries requiring superior electrical/thermal conductivity and corrosion resistance. This guide explores the technical nuances of copper CNC machining and how our expertise ensures unmatched quality.

Why Choose CNC Machining for Copper Components?

Copper's unique properties demand specialized machining approaches. Our CNC copper parts processing capabilities address:

High ductility challenges through optimized tool paths

Thermal management with advanced cooling systems

Surface finish requirements (Ra .8μm achievable)

Tight tolerances (±.01mm standard)

AOOM's Copper Machining Process Flow

Our certified CNC copper parts processing workflow includes:

Material certification (C11000, C10100, etc.)

CAD/CAM programming with deformation compensation

High-speed machining (20,000+ RPM spindles)

In-process quality inspection (CMM available)

Surface treatment options (electropolishing, passivation)

Industry Applications We Serve

From electrical busbars to semiconductor components, our copper machining serves:

Power distribution systems

EV battery thermal management

RF waveguide components

Medical gas delivery systems

With ISO 9001-certified production and 15+ years of copper machining experience, AOOM Technology guarantees precision, reliability, and on-time delivery for your most demanding copper component requirements.