CNC Machining Manufacturing Factory

In today's competitive manufacturing landscape, finding a reliable CNC machining manufacturing factory is critical for businesses seeking precision, efficiency, and scalability. AOOM Technologies specializes in delivering high-quality CNC machining solutions tailored to industries ranging from aerospace to medical devices. This article explores the key considerations when selecting a partner and how our expertise ensures superior results.

What Defines a Top-Tier CNC Machining Factory?

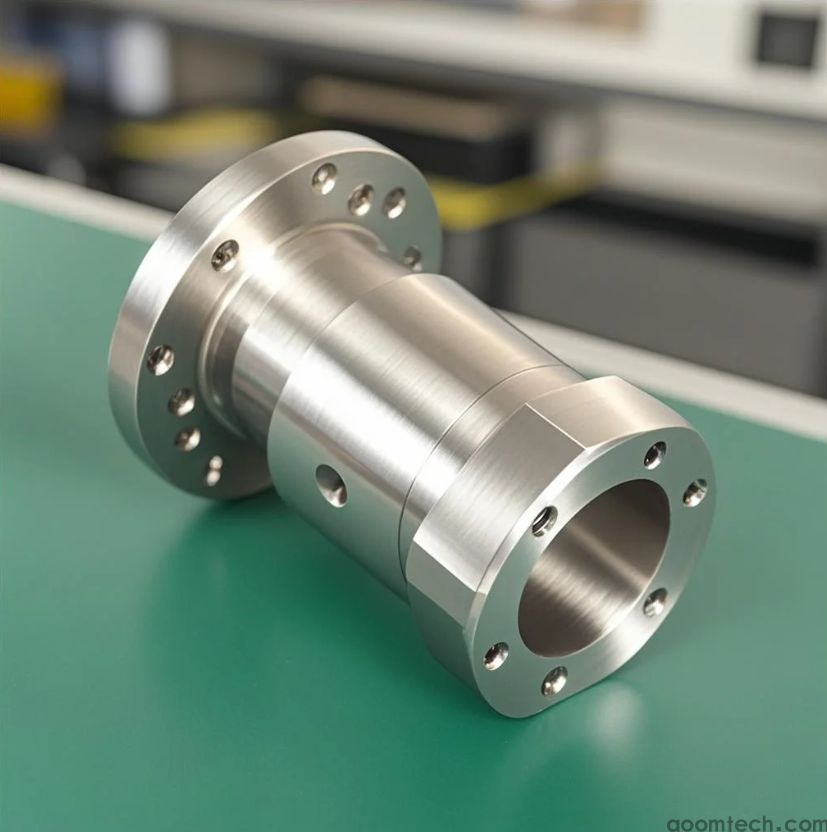

A leading CNC machining factory combines advanced technology with rigorous quality control. At AOOM, we operate state-of-the-art 5-axis CNC machines capable of achieving tolerances within ±.005mm. Our ISO 9001-certified processes encompass material selection, precision programming, and post-processing treatments like anodizing or heat treatment to meet diverse industrial requirements.

Key Advantages of Partnering with AOOM

1. Material Versatility: We machine aluminum, titanium, stainless steel, and engineering plastics

2. Rapid Prototyping: 3-5 day turnaround for functional prototypes

3. Scalable Production: Capacity for both low-volume batches and mass production

4. Quality Assurance: Every component undergoes CMM inspection and surface roughness testing

Industry-Specific Solutions

Our factory serves specialized sectors with tailored approaches:

- Automotive: Engine components with tight geometric tolerances

- Electronics: EMI/RFI shielding enclosures with precision cooling channels

- Medical: Biocompatible implants meeting FDA/GMP standards

With 15+ years of experience, AOOM Technologies has established itself as a trusted CNC machining manufacturing factory through consistent delivery of dimensionally accurate, functionally optimized parts. Our engineers work closely with clients from DFM analysis to final inspection, ensuring cost-efficiency without compromising quality.