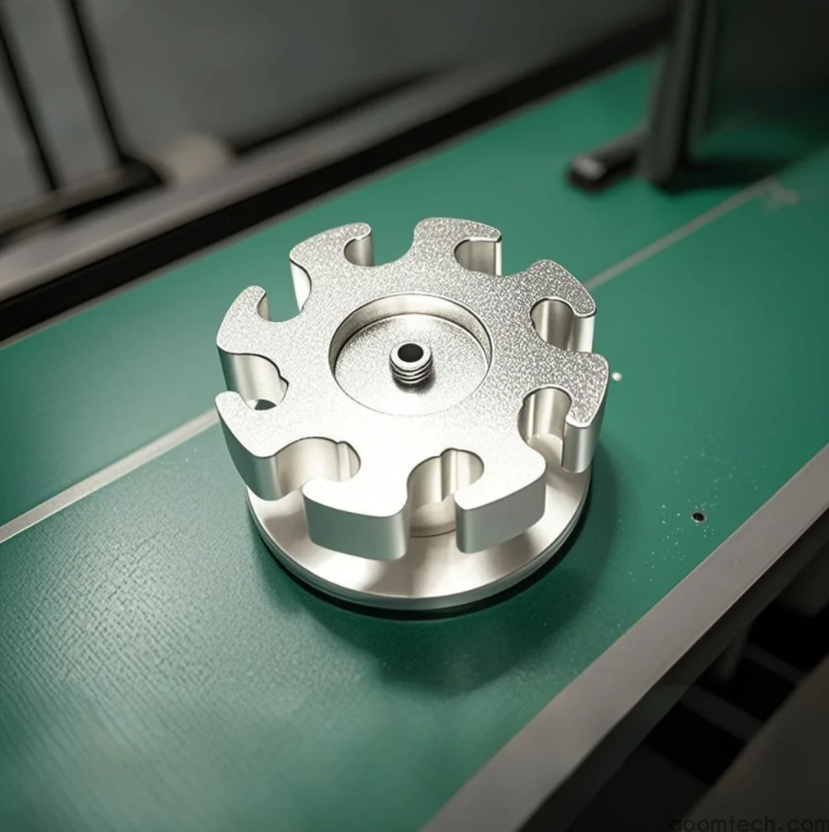

CNC Machining Process for Aircraft Components

As a professional CNC machining service provider, AOOM Technology specializes in manufacturing high-precision aircraft components with strict tolerances and superior surface finishes. This article explores the critical aspects of CNC machining aircraft parts, addressing common industry challenges and showcasing our technical capabilities.

Why Choose CNC Machining for Aircraft Components?

Aerospace applications demand extreme precision and reliability. CNC machining offers unmatched accuracy (up to ±.001mm) for complex geometries in materials like titanium, aluminum alloys, and high-temperature composites. Our 5-axis CNC centers at AOOM Technology can produce lightweight yet structurally sound components that meet AS910 and NADCAP standards.

Key Processes in Aircraft Part Manufacturing

1. Material Selection: We work with aerospace-grade aluminum (7075, 6061), titanium (Grade 5), and Inconel

2. Precision Milling/Turning: Multi-axis simultaneous machining for complex contours

3. Surface Treatment: Anodizing, chemical conversion coatings, and specialized plating

4. Quality Assurance: CMM inspection and ultrasonic testing for defect detection

AOOM's Technical Advantages

Our facility features:

- 15+ high-speed CNC machining centers (Mazak, DMG Mori)

- In-house heat treatment and surface coating capabilities

- Full traceability from raw material to finished part

- 24/7 production capacity for urgent aerospace orders

For CNC machining aircraft components that meet rigorous aerospace standards, visit AOOM Technology to request a quote or discuss your project requirements with our engineering team.