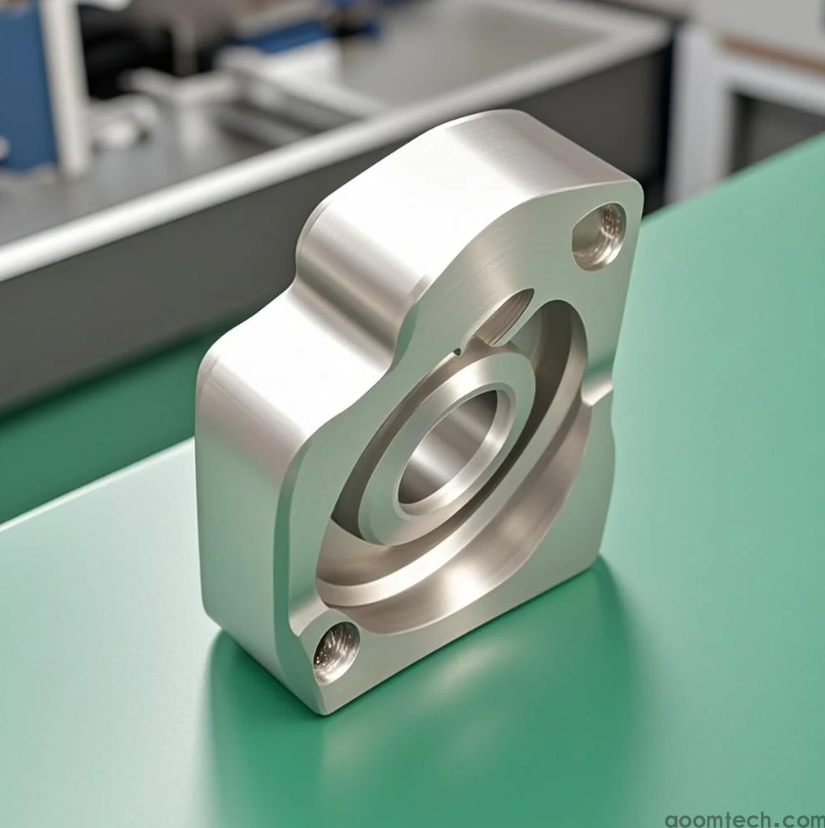

CNC Machining Valve Components

As a leading CNC machining service provider, AOOM Technology specializes in manufacturing precision valve components for various industrial applications. This article explores the technical aspects and advantages of our valve parts production.

Why Choose CNC Machining for Valve Components?

Valve components require exceptional dimensional accuracy and surface finish to ensure proper sealing and longevity. Our CNC machining processes deliver tight tolerances (up to ±.005mm) and superior surface quality (Ra .4μm achievable), making them ideal for critical fluid control applications.

Materials We Process

We machine valve components from various materials including:

- Stainless steel (304, 316, 17-4PH)

- Brass and bronze alloys

- Titanium

- High-performance plastics (PEEK, PTFE)

Each material undergoes strict quality control to meet industry standards.

Our CNC Machining Capabilities

AOOM Technology's advanced CNC machining centers can produce:

- Valve bodies and housings

- Stems and spindles

- Seats and discs

- Custom valve trim components

We employ multi-axis machining for complex geometries and complete parts in single setups.

Quality Assurance

Every valve component undergoes rigorous inspection including:

- CMM measurement

- Surface roughness testing

- Pressure testing (when required)

- Material certification

Our ISO 9001-certified system ensures consistent quality across all productions.

Why Partner with AOOM Technology?

With 15+ years of experience in precision CNC machining, we offer:

- Short lead times (as fast as 5 days)

- Competitive pricing for bulk orders

- DFM support for optimal valve designs

- Complete confidentiality for proprietary components

Visit our website at www.aoomtech.com to request a quote or discuss your valve component requirements with our engineering team.