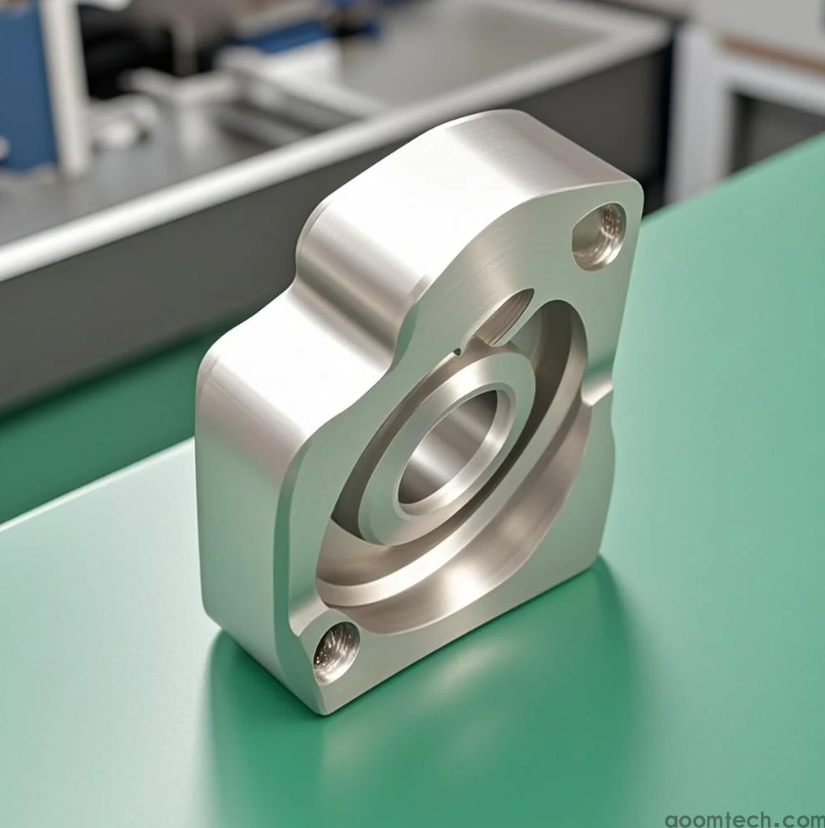

CNC Machining Boiler Precision Components

As a leading CNC machining service provider, AOOM Technologies specializes in manufacturing high-precision boiler components that meet stringent industry standards. This article explores the technical considerations and value propositions for procurement professionals seeking reliable partners for critical thermal equipment parts.

Why Choose CNC Machining for Boiler Components?

Boiler systems demand components with exceptional dimensional accuracy and material integrity. Our CNC machining processes deliver:

- ±.01mm tolerance for perfect sealing surfaces

- Superior heat resistance through controlled material grain structure

- Complex geometries achievable in single setups

- ASME Section I and VIII compliant manufacturing

Material Selection for High-Temperature Applications

We machine premium-grade materials including SA-516 Grade 70, Inconel 625, and 316L stainless steel, selected based on:

- Operating temperature ranges (up to 1,200°F continuous service)

- Corrosion resistance requirements

- Pressure vessel design specifications

AOOM's Quality Assurance Protocol

Every boiler precision component undergoes:

- 3D scanning for dimensional verification

- UT/RT testing for critical pressure parts

- Surface roughness analysis (Ra ≤ 3.2 μm for gasket surfaces)

- Material certification traceability

Engineering Support Services

Our technical team provides:

- DFM analysis to optimize machining costs

- Thermal expansion compensation calculations

- ASME Code Stamp documentation support

- Emergency replacement part turnaround (72-hour service available)

Explore our CNC machining capabilities for boiler systems at AOOM Technologies, where we combine precision engineering with industry-specific expertise to deliver components that outperform in the most demanding thermal environments.