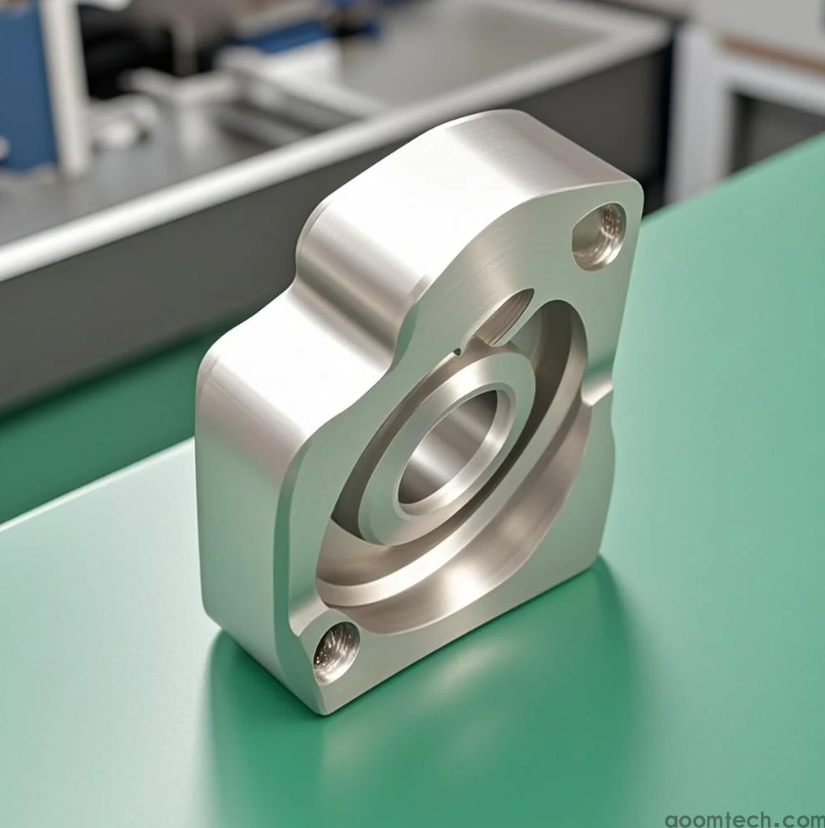

CNC Medical Device Parts Machining

Precision Manufacturing for Critical Healthcare Applications

CNC medical device parts machining requires the highest levels of precision, quality control, and material expertise. At AOOM, we specialize in manufacturing complex medical components that meet stringent industry standards and regulatory requirements.

Why Choose CNC Machining for Medical Components?

Medical device manufacturers rely on CNC machining for several critical reasons:

- Exceptional dimensional accuracy (±.005mm tolerance achievable)

- Superior surface finishes required for medical applications

- Ability to work with biocompatible materials like titanium, stainless steel, and PEEK

- Repeatable precision for high-volume production

- Complex geometries achievable in single setups

Our Medical CNC Machining Capabilities

AOOM's state-of-the-art CNC machining centers deliver:

- 5-axis machining for complex surgical instrument components

- Micro-machining for miniature medical devices

- Cleanroom manufacturing options when required

- Full material traceability and certification

- Surface treatments including anodizing, passivation, and electropolishing

Materials We Machine for Medical Applications

We work with all medical-grade materials including:

- Titanium (Grade 2, 5, 23)

- Stainless Steel (316L, 17-4PH, 304)

- Cobalt Chrome alloys

- Medical Plastics (PEEK, Ultem, PTFE)

- Aluminum (for non-implantable devices)

Quality Assurance and Compliance

Our quality management system ensures:

- ISO 13485:2016 certified processes

- Full documentation for FDA submissions

- First article inspection and in-process quality checks

- Material certifications and test reports

- Sterilization-compatible packaging

Partner with AOOM for Your Medical Machining Needs

With extensive experience in CNC medical device parts machining, AOOM provides the precision, quality, and regulatory compliance your medical projects demand. Our team understands the critical nature of medical components and works closely with clients from prototype through production.

Contact us today to discuss your specific medical machining requirements and learn how we can support your next project with our advanced CNC capabilities.