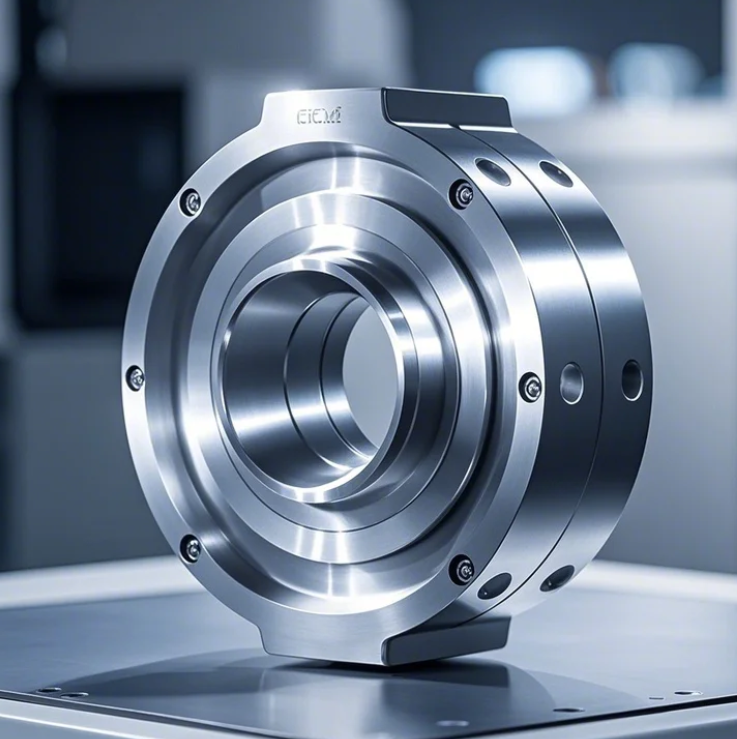

Aluminum CNC Machining: Precision Solutions for Your Manufacturing Needs

When it comes to aluminum CNC machining, precision, efficiency, and material expertise are critical. At AOOM, we specialize in delivering high-quality CNC-machined aluminum components tailored to industries ranging from aerospace to automotive. This article explores the process, advantages, and applications of aluminum CNC machining, showcasing why AOOM is your ideal manufacturing partner.

Why Choose Aluminum for CNC Machining?

Aluminum is a preferred material in CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. Its malleability allows for intricate designs while maintaining structural integrity, making it ideal for high-precision parts. Common grades like 6061 and 7075 are widely used in industries requiring lightweight yet durable components.

AOOM's Aluminum CNC Machining Capabilities

Our state-of-the-art CNC machines and ISO-certified processes ensure tight tolerances (up to ±.005mm) and superior surface finishes. We handle:

- Prototyping and mass production

- Complex geometries (e.g., thin walls, deep cavities)

- Multi-axis machining (3/4/5-axis)

With in-house quality control and material traceability, we guarantee consistency across every batch.

Applications Across Industries

From aerospace brackets to automotive heat sinks, our aluminum CNC parts meet rigorous industry standards. Partner with AOOM for reliable, cost-effective solutions backed by 15+ years of machining expertise. Contact us today for a quote or design consultation.