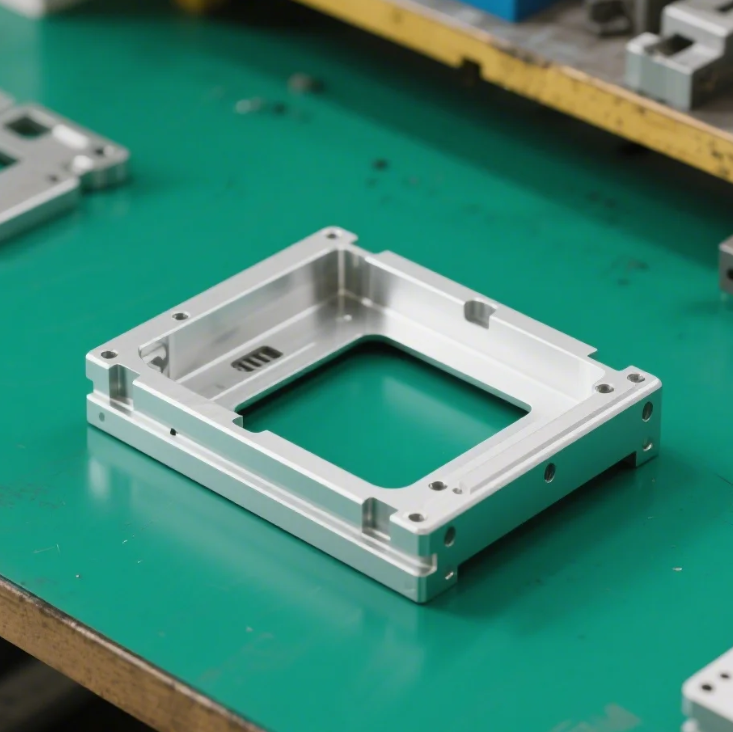

Aluminum Alloy Enclosure CNC Machining

In modern manufacturing, aluminum alloy enclosure CNC machining plays a pivotal role in producing high-precision, durable, and lightweight components for industries ranging from electronics to aerospace. At AOOM, we specialize in delivering top-tier CNC machining solutions tailored to meet your specific requirements.

Why Choose Aluminum Alloy for CNC Machining?

Aluminum alloy is a preferred material for enclosures due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. These properties make it ideal for applications where durability and performance are critical. Our advanced CNC machining techniques ensure precise dimensions and smooth finishes, meeting the highest industry standards.

Our CNC Machining Process

At AOOM, we follow a meticulous process to ensure the highest quality output:

- Design & Prototyping: Our team collaborates with clients to refine designs and create prototypes using CAD/CAM software.

- Material Selection: We source premium-grade aluminum alloys to guarantee optimal performance.

- Precision Machining: Utilizing state-of-the-art CNC machines, we achieve tight tolerances and complex geometries.

- Quality Inspection: Every part undergoes rigorous testing to ensure compliance with specifications.

Applications of Aluminum Alloy Enclosures

Our aluminum alloy enclosures are widely used in:

- Electronics: Housing for sensitive equipment requiring EMI shielding.

- Automotive: Lightweight components for enhanced fuel efficiency.

- Medical: Sterile and durable casings for devices.

- Aerospace: High-strength parts resistant to extreme conditions.

Why Partner with AOOM?

AOOM stands out as a trusted CNC machining partner due to our:

- 15+ years of industry expertise.

- ISO 9001-certified quality management.

- Fast turnaround and competitive pricing.

- End-to-end support from design to delivery.

Visit aoomtech.com to explore our capabilities or request a quote today!