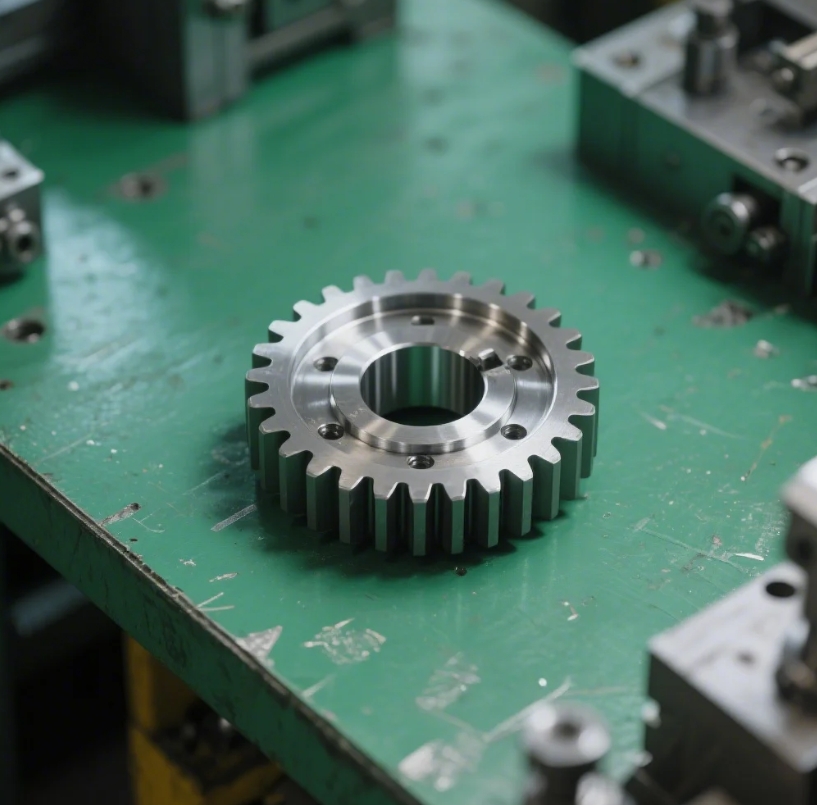

CNC Gear Machining: Precision Solutions for Industrial Applications

In modern manufacturing, CNC gear machining plays a pivotal role in producing high-precision components for automotive, aerospace, and robotics industries. As a leading CNC machining service provider, AOOM Technologies delivers unmatched expertise in crafting gears with micron-level accuracy, ensuring optimal performance and durability.

Why Choose CNC for Gear Manufacturing?

CNC technology enables the production of complex gear profiles (spur, helical, bevel, etc.) with tolerances as tight as ±.005mm. Our 5-axis CNC mills and Swiss-type lathes at AOOMTech can handle materials ranging from aluminum alloys to hardened steels, achieving surface finishes down to Ra .4μm.

Key Advantages of Our CNC Gear Machining

1. Material Versatility: Process brass, titanium, PEEK, and other engineering plastics

2. Custom Solutions: Prototype to mass production (up to 50,000 units/month)

3. Quality Assurance: ISO 9001-certified with CMM inspection for every batch

End-to-End Gear Production Capabilities

From CAD/CAM programming to post-machining treatments (heat treatment, grinding, or coating), AOOMTech provides complete gear manufacturing services. Our engineers optimize tool paths to minimize production time while maintaining AGMA quality standards.

Discover how our CNC gear machining can enhance your mechanical systems' efficiency. Visit aoomtech.com for technical consultation and instant quoting.