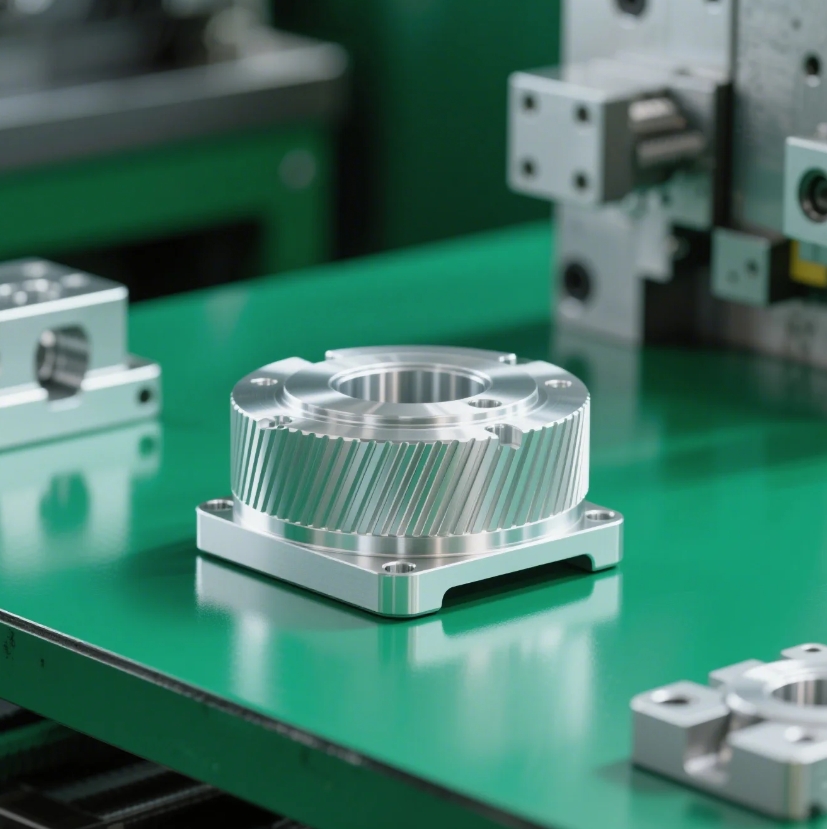

CNC Aluminum Parts Batch Processing: Precision and Efficiency for Your Production Needs

When it comes to CNC aluminum parts batch processing, manufacturers demand a combination of precision, speed, and cost-effectiveness. At AOOM, we specialize in delivering high-quality CNC-machined aluminum components tailored for large-scale production, ensuring your projects meet both technical specifications and tight deadlines.

Why Choose CNC Aluminum Parts Batch Processing?

Batch processing of aluminum parts via CNC machining offers unparalleled advantages for industries ranging from aerospace to automotive and electronics. Our advanced CNC technology guarantees:

- Consistent precision across all parts in the batch

- Reduced per-unit costs through optimized production

- Faster turnaround times compared to traditional methods

- Excellent surface finishes and tight tolerances

Our Advanced CNC Machining Capabilities

AOOM's state-of-the-art facility features multi-axis CNC machines capable of handling complex aluminum parts geometries with micron-level accuracy. Our team of skilled technicians implements rigorous quality control measures throughout the batch processing workflow, from material selection to final inspection.

Materials We Work With

While specializing in aluminum alloys (including 6061, 7075, and 5052), we also process:

- Stainless steel

- Brass

- Titanium

- Engineering plastics

Quality Assurance in Batch Production

Every batch undergoes comprehensive testing, including:

- Dimensional verification with CMM

- Surface roughness measurement

- Material certification

- Functional testing when required

With AOOM as your manufacturing partner, you gain access to reliable CNC aluminum parts batch processing that combines German-engineered precision with competitive pricing. Contact our team today to discuss your project requirements and receive a customized quote.