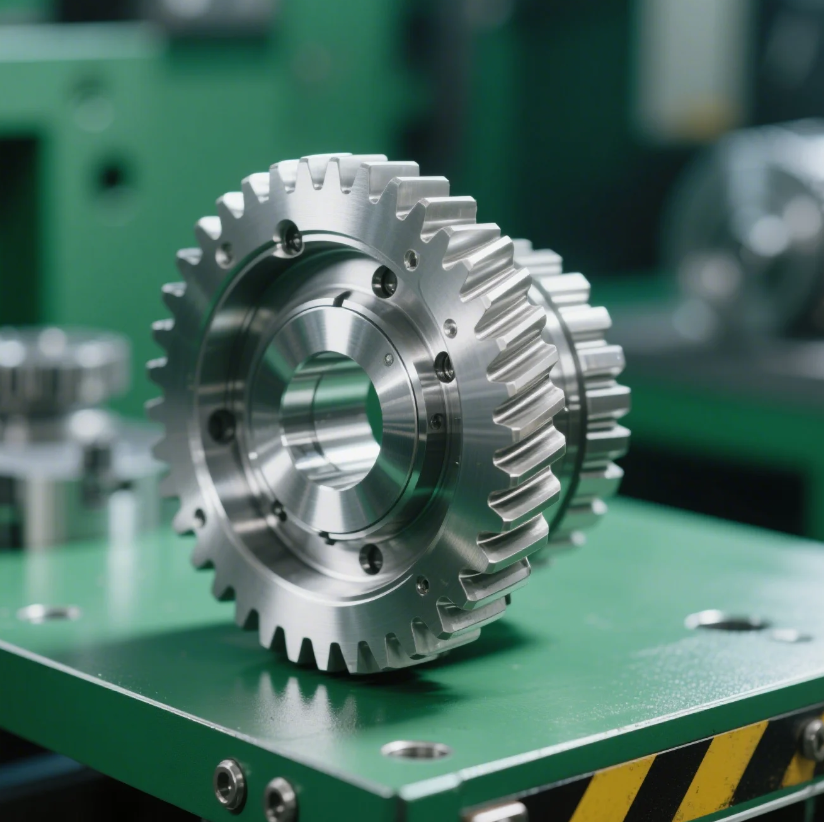

CNC Machining Gears: Precision Manufacturing Solutions for Your Applications

In modern manufacturing, CNC machining gears has become a critical process for industries requiring high-precision motion transmission components. As a leading CNC machining service provider, AOOM Technology delivers exceptional gear manufacturing solutions tailored to your specific requirements.

Why Choose CNC Machining for Gear Production?

CNC machining offers unparalleled advantages in gear manufacturing. The computer-controlled process ensures micron-level accuracy in tooth profile, pitch, and surface finish. Our 5-axis CNC machines can produce spur gears, helical gears, bevel gears, and worm gears with complex geometries that would be challenging with conventional methods.

Materials for CNC Machined Gears

We work with various materials to meet different operational needs:

- Aluminum alloys (lightweight and corrosion-resistant)

- Stainless steel (for high strength and durability)

- Brass (excellent wear resistance)

- Engineering plastics (for noise reduction)

Each material selection is carefully considered based on your application's load, speed, and environmental factors.

Our CNC Gear Machining Capabilities

AOOM Technology's CNC machining services cover the entire gear production process:

- Precision gear hobbing and shaping

- Custom gear design and prototyping

- Heat treatment and surface finishing

- Quality inspection with coordinate measuring machines

Our team of experienced engineers ensures every gear meets or exceeds industry standards like AGMA and ISO.

Applications of CNC Machined Gears

Our precision gears serve various industries including:

- Automotive transmissions

- Industrial machinery

- Robotics and automation systems

- Aerospace components

Whether you need prototype quantities or mass production, we can scale to meet your demands.

Why Partner with AOOM Technology?

Choosing AOOM Technology for your gear machining needs means:

- 30+ years of combined CNC machining expertise

- State-of-the-art machining centers

- Strict quality control processes

- Competitive pricing and fast turnaround

- Comprehensive technical support

Contact our engineering team today to discuss your gear manufacturing requirements and receive a free project evaluation.