CNC Machining of Golf Club Molds

Precision Manufacturing for Golf Equipment

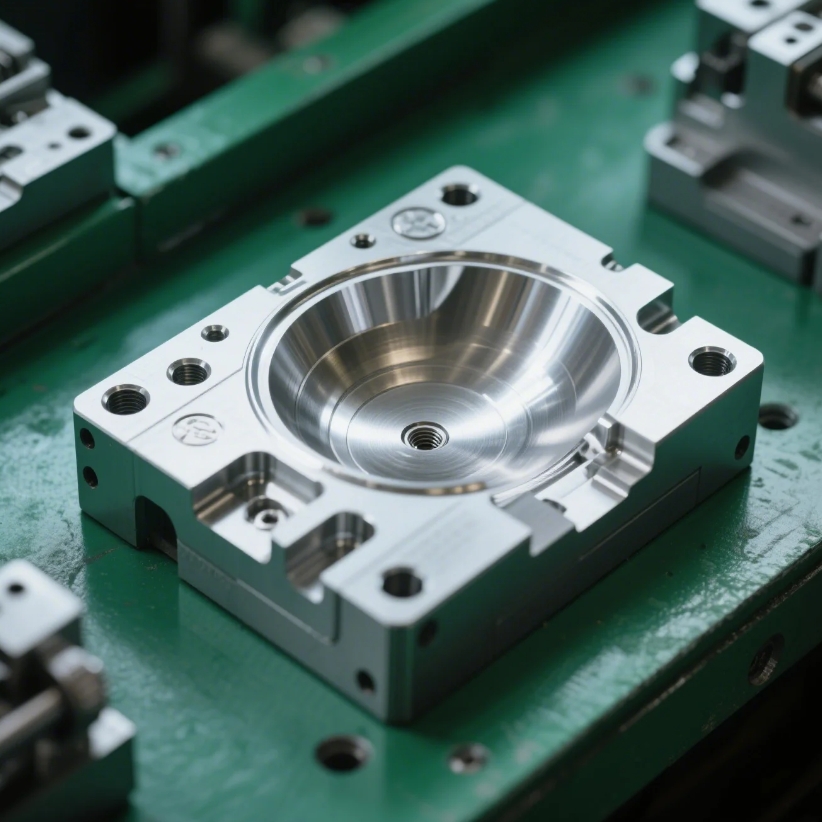

As a leading CNC machining specialist, AOOM Technology provides high-precision golf mold manufacturing services for club heads, putters, and other golf equipment components. Our advanced 5-axis CNC machines deliver micron-level accuracy required for competitive golf equipment production.

Why Choose AOOM for Your Golf Mold Needs?

1. Material Expertise: We machine various mold materials including tool steels, aluminum alloys, and copper alloys specifically selected for golf equipment durability.

2. Surface Finish Excellence: Our polishing and texturing processes create the perfect surface finishes for golf club molds, ensuring consistent product quality.

3. Rapid Prototyping: From design to production, we accelerate your golf product development cycle with fast-turnaround CNC machining services.

Complete Golf Mold Manufacturing Process

Our end-to-end manufacturing process includes CAD/CAM programming, precision machining, EDM services when required, quality inspection, and post-processing - all performed in our ISO-certified facility with strict quality control measures.

Technical Specifications

- Tolerance: ±.01mm

Maximum Mold Size: 150×800×500mm

Surface Roughness: Ra .2μm achievable

Secondary Services: Heat treatment, coating, assembly