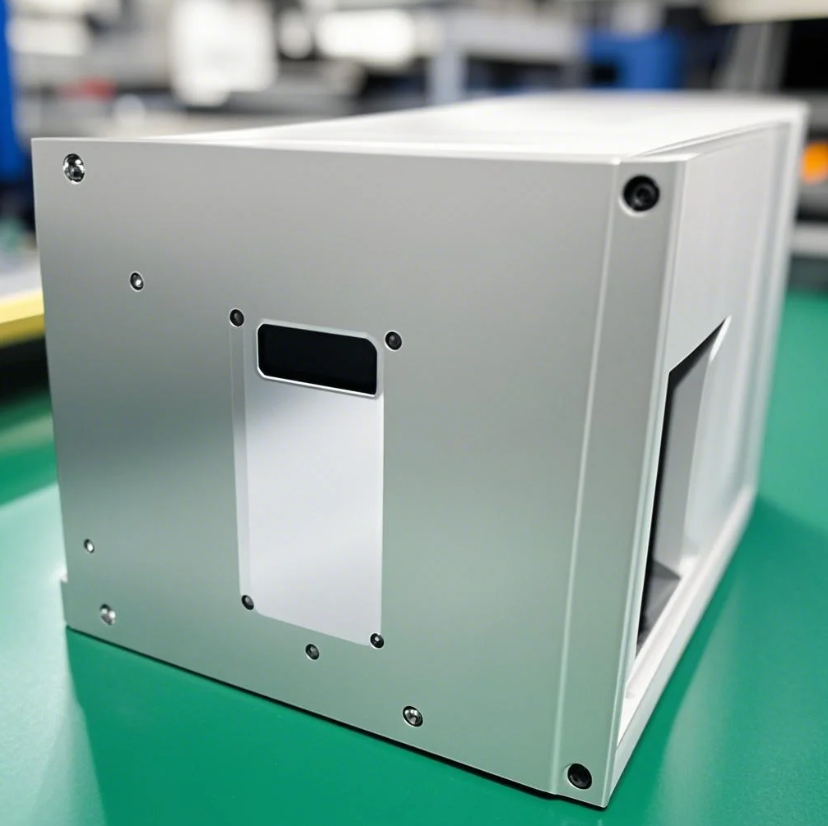

Communication Enclosure CNC Machining

In the rapidly evolving field of telecommunications, precision and durability are non-negotiable. Communication enclosure CNC machining plays a pivotal role in manufacturing robust, high-performance enclosures that protect sensitive electronic components from environmental hazards. At AOOM, we specialize in delivering CNC-machined enclosures tailored to meet the stringent demands of the telecom industry.

Why Choose CNC Machining for Communication Enclosures?

CNC machining offers unparalleled accuracy, repeatability, and material versatility for fabricating communication enclosures. Whether you require aluminum, stainless steel, or engineering plastics, our CNC machining services ensure tight tolerances (±.01mm), smooth finishes, and complex geometries to accommodate intricate designs like heat dissipation channels or EMI shielding features.

Key Advantages of AOOM's CNC Machining Solutions

- Material Expertise: We machine enclosures from 6061-T6 aluminum (lightweight & corrosion-resistant), 304 stainless steel (durable), and PEEK (high-temperature resistance).

- IP-Rated Protection: Precision-machined grooves for gaskets ensure IP67/IP68 compliance against dust and water ingress.

- Rapid Prototyping: Accelerate product development with our 3-5 day lead time for prototype enclosures.

Applications Across Telecom Infrastructure

From 5G base stations to fiber optic terminal boxes, our CNC-machined enclosures are trusted by global telecom OEMs. Case in point: We recently delivered 500+ weatherproof aluminum enclosures for a Tier-1 provider, achieving 100% dimensional compliance per IEC 61969-2 standards.

Ready to optimize your communication hardware? Contact AOOM today for a free DFM analysis and quote tailored to your enclosure requirements.