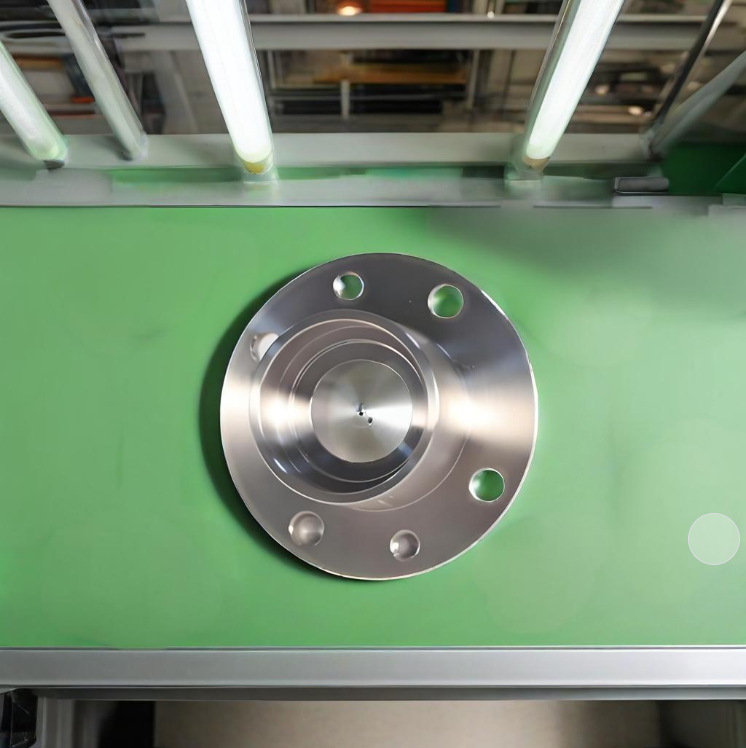

Non-Standard Precision CNC Machining

What is Non-Standard Precision CNC Machining?

Non-standard precision CNC machining refers to the process of creating custom, complex, and high-accuracy parts that don't conform to standard specifications. Unlike mass-produced components, these parts require specialized programming, tooling, and quality control to meet unique design requirements.

Key Advantages of Our Non-Standard CNC Machining Services

At AOOM, we specialize in delivering precision CNC machining solutions for non-standard components. Our capabilities include:

- Tolerances as tight as ±.001" (±.025mm)

- Complex geometries with 5-axis machining

- Custom material specifications

- Prototype to full production runs

Industries We Serve

Our non-standard CNC machining expertise benefits various industries including aerospace, medical devices, automotive, and industrial equipment. We understand the stringent requirements of these sectors and deliver parts that meet or exceed expectations.

Why Choose AOOM for Your Non-Standard CNC Needs?

With state-of-the-art CNC equipment and a team of skilled technicians, AOOM provides:

- DFM (Design for Manufacturing) consultation

- Rapid prototyping services

- Comprehensive quality assurance

- Competitive pricing for custom parts

Our Precision Machining Process

Every non-standard project follows our rigorous production process:

- Engineering review and feasibility analysis

- Custom CNC programming

- Precision machining with real-time monitoring

- Stringent quality inspection

- Careful packaging and delivery

Get Started with Your Custom CNC Project

Contact AOOM today to discuss your non-standard precision machining requirements. Our team is ready to provide expert guidance and deliver components that meet your exact specifications with unmatched accuracy and quality.