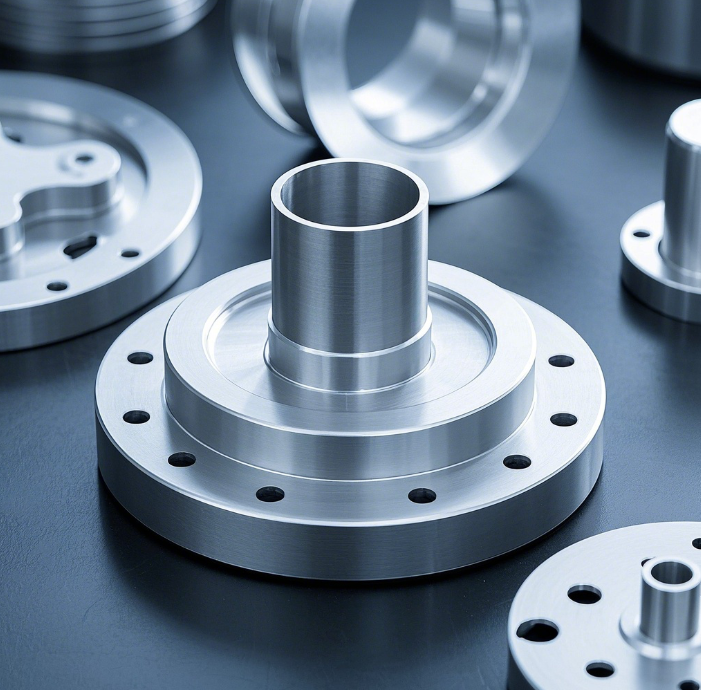

Precision Aluminum CNC Machining Services for Industrial Applications

When it comes to aluminum CNC machining, AOOM stands as your trusted partner for high-precision components. Our advanced manufacturing capabilities ensure exceptional quality for aerospace, automotive, and electronics industries.

Why Choose Aluminum for CNC Machining?

Aluminum alloys offer the perfect balance of strength, weight, and machinability. Our CNC machining processes leverage aluminum's excellent thermal conductivity and corrosion resistance to create complex parts with tight tolerances (±.005mm).

Our Aluminum CNC Machining Capabilities

AOOM's 5-axis CNC centers deliver unmatched precision for:

- Aerospace components (brackets, housings)

- Automotive prototypes (engine parts, mounts)

- Electronic enclosures and heat sinks

- Medical device components

Quality Assurance Process

Every aluminum machined part undergoes rigorous inspection using CMM and surface roughness testers. We maintain ISO 9001 certification and provide full material traceability with mill test reports.

Advantages of Partnering with AOOM

1. 15+ years of CNC machining expertise

2. Fast turnaround (prototypes in 5-7 days)

3. Competitive pricing with volume discounts

4. DFM support from our engineering team

Visit www.sjt-ic.com to request a free project evaluation and quote for your aluminum CNC machining needs.