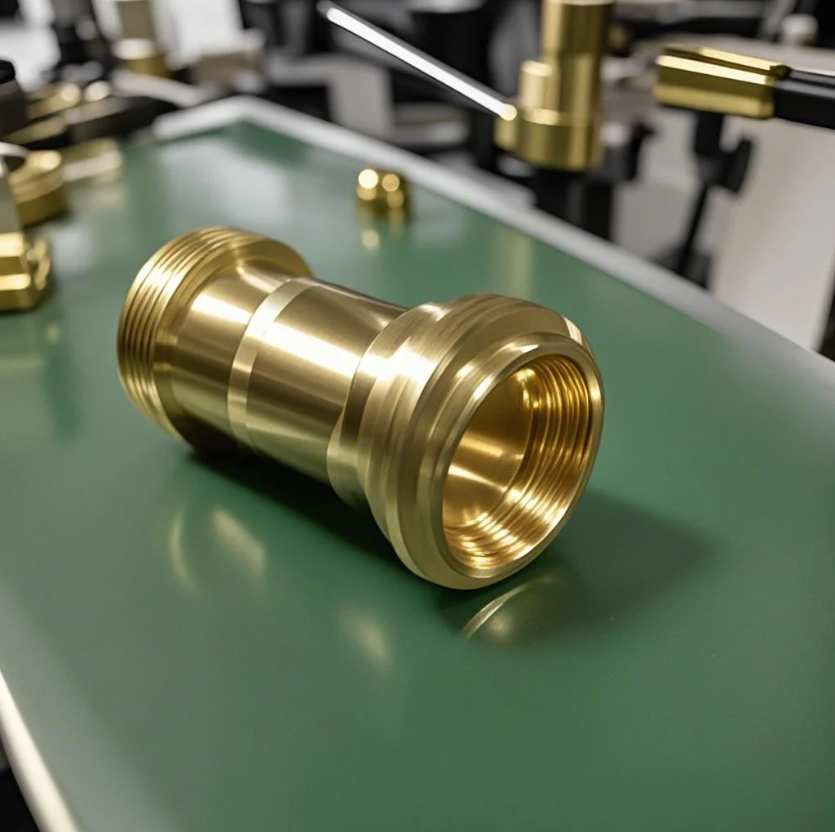

Copper Parts CNC Batch Machining: Precision Manufacturing for High-Volume Needs

In industries requiring durable, high-precision metal components, copper parts CNC batch machining is a critical solution. AOOM Technologies specializes in delivering cost-effective, large-scale production of copper components with micron-level accuracy, catering to sectors like electronics, automotive, and industrial equipment.

Why Choose CNC Machining for Copper Batch Production?

Copper's exceptional conductivity and corrosion resistance make it ideal for electrical and thermal applications. However, its softness poses machining challenges. Our CNC batch processing addresses this through:

- Rigid machine structures minimizing vibration

- Optimized tool paths preventing material deformation

- Advanced coolant systems maintaining dimensional stability

AOOM's Batch Machining Capabilities

Our 15,000㎡ facility houses 80+ CNC centers equipped for copper-specific processing:

- Volume Range: 500-100,000+ units per batch

- Tolerances: Down to ±.005mm

- Materials: C11000, C10100, C14500, and alloy variants

Cost-Saving Advantages of Batch Processing

Through optimized CNC batch workflows, we deliver 30-45% cost reductions versus small-run production via:

- Dedicated fixture systems reducing setup time

- Automated tool changers maximizing spindle utilization

- Statistical process control minimizing material waste

From bushings to complex heat sinks, our copper batch machining combines material expertise with advanced CNC technology. Request a project evaluation at www.aoomtech.com to receive DFM feedback and volume pricing within 24 hours.