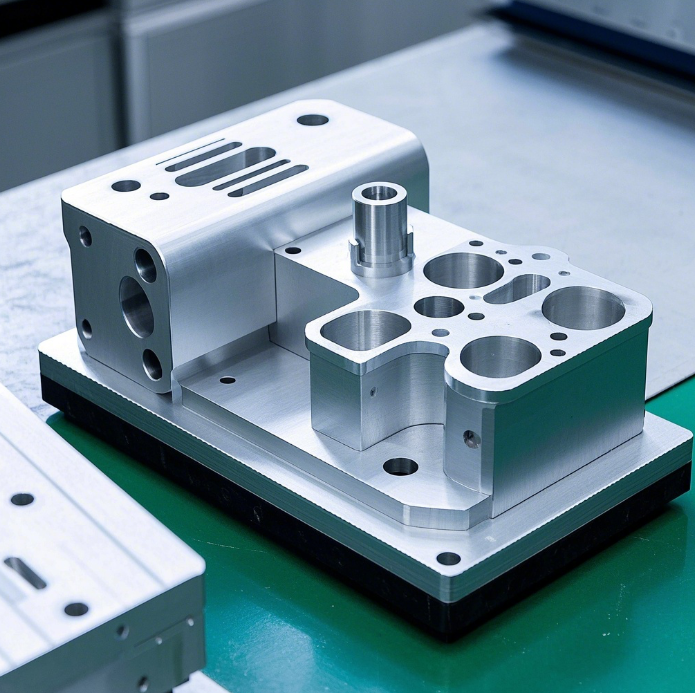

Precision CNC Machining for Large Aluminum Parts: Solutions & Benefits

As a leading provider of CNC machining services, AOOM specializes in manufacturing high-precision large aluminum components for industries ranging from aerospace to automotive. This article explores the technical advantages, process capabilities, and quality assurance behind our CNC aluminum machining solutions.

Why Choose CNC Machining for Large Aluminum Components?

Large aluminum parts require exceptional dimensional stability and surface finish - challenges perfectly addressed by our 5-axis CNC centers. AOOM's machines achieve ±.01mm tolerances on workpieces up to 2,000mm in length, combining high-speed cutting with advanced cooling systems to prevent thermal deformation.

Key Process Capabilities at AOOM

Our facility features:

- Multi-axis simultaneous machining for complex geometries

- Custom fixture design for vibration-free heavy cutting

- In-process measurement with CMM verification

- Anodizing and other post-processing options

Industry-Specific Applications

We regularly produce:

- Aircraft structural components (grade 7075-T6)

- Automotive battery housings (die-cast aluminum)

- Industrial automation frames (extruded 6061)

Quality Assurance Protocol

Every project undergoes:

- Material certification verification

- Toolpath simulation before machining

- First-article inspection with 3D scanning

- Final dimensional report with GD&T analysis

Visit AOOM's official website to request a free DFM analysis for your next large aluminum part project. Our engineering team provides technical consultation within 24 hours.