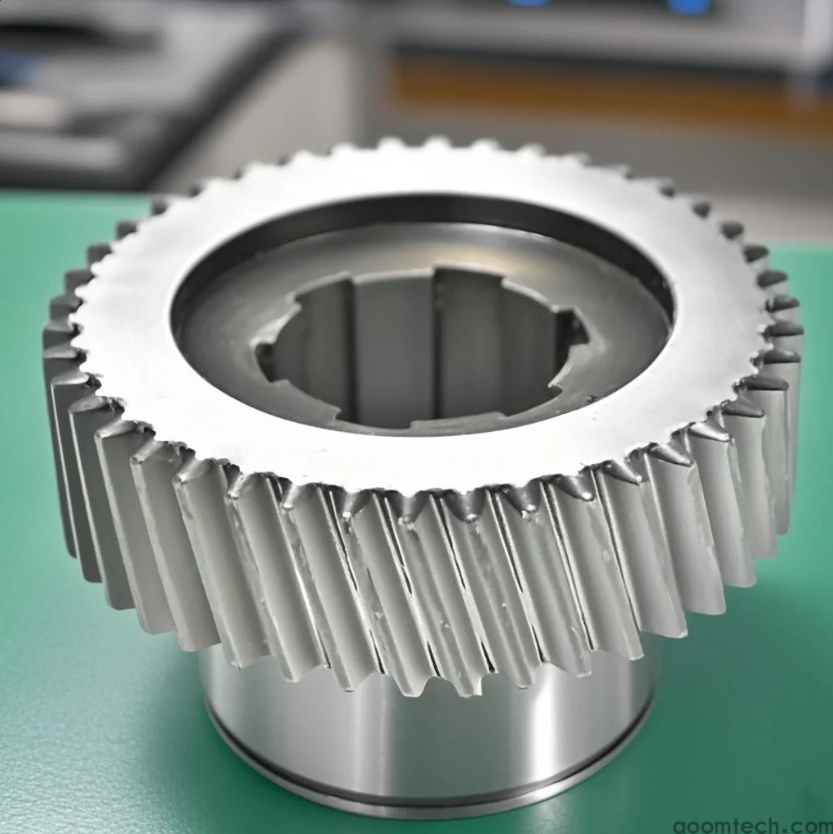

CNC Motor Gear Machining

In precision manufacturing, CNC motor gear machining stands as a critical process for industries requiring high-torque transmission components. AOOM Technology specializes in delivering micron-level accuracy for motor gears across automotive, robotics, and industrial automation sectors.

The CNC Machining Process for Motor Gears

Our 5-axis CNC centers perform complete gear fabrication in a single setup, including:

- Blank preparation with stress-relieved materials

- Precision tooth profiling with helical/bevel capabilities

- Heat treatment integration (case hardening or nitriding)

- Final finishing via grinding or honing

Material Selection for Optimal Performance

We machine CNC motor gears from:

• 414/434 alloy steels (58-62 HRC after treatment)

• Stainless steel 17-4PH for corrosive environments

• Brass/bronze for low-noise applications

• Engineering plastics like PEEK for lightweight needs

Quality Assurance Protocols

Every gear undergoes:

- 3D scanning against original CAD models

- CMM inspection for dimensional accuracy

- Surface roughness testing (Ra ≤ .4μm)

- Dynamic balancing for high-RPM applications

AOOM's CNC gear machining with typical lead times of 5-7 days for prototype batches. Our ISO 9001-certified facility in Shenzhen supports global clients with DFM analysis and full traceability documentation.