CNC Machining Product Parts: Precision, Efficiency, and Custom Solutions

As a leading CNC machining service provider, AOOM Technologies specializes in manufacturing high-precision CNC machined product parts for diverse industries. This article explores the technical aspects, quality control, and value-added services that set us apart in the competitive CNC manufacturing landscape.

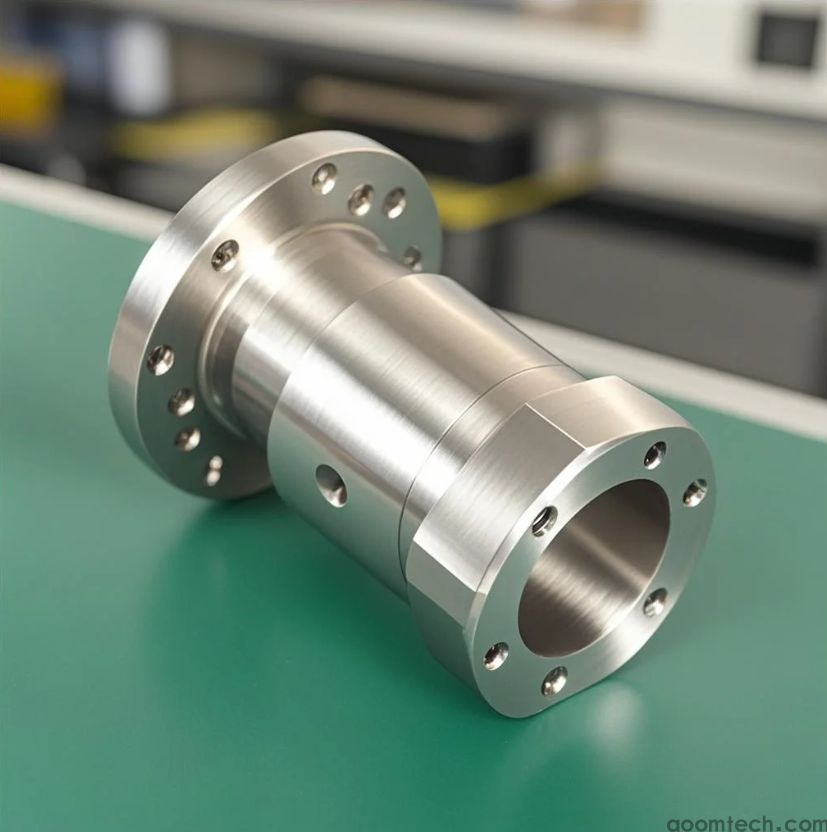

Understanding CNC Machined Product Components

CNC machining transforms raw materials into precision parts through computer-controlled subtractive manufacturing. Our 3- to 5-axis CNC mills and lathes produce components with tolerances as tight as ±.005mm, suitable for aerospace, automotive, medical, and industrial applications. The process begins with CAD model analysis, followed by strategic toolpath programming to optimize material removal rates while maintaining dimensional accuracy.

Material Selection for Optimal Performance

We machine product parts from various engineering-grade materials:

- Metals: Aluminum (6061-T6, 7075), stainless steel (303, 304, 316), titanium, brass

- Plastics: PEEK, Delrin, PTFE, Ultem

- Composites: G10, carbon fiber reinforced polymers

Material selection considers functional requirements, environmental factors, and cost-efficiency.

Quality Assurance Protocols

AOOM implements rigorous quality control measures:

- First-article inspection (FAI) with CMM verification

- In-process dimensional checks using calibrated micrometers

- Surface roughness measurement (Ra .4-3.2 μm achievable)

- Material certification traceability

Our ISO 9001-certified system ensures consistent part-to-part repeatability.

Value-Added Services

Beyond standard machining, we provide:

- Secondary operations (anodizing, plating, heat treatment)

- Assembly and kitting services

- Just-in-time delivery programs

- Engineering support for DFM optimization

These services streamline supply chains for OEMs and contract manufacturers.

Why Choose AOOM for CNC Product Parts?

Our advantages include:

- 15+ years of aerospace-grade machining experience

- 50+ CNC machines with automatic tool changers

- ERP-integrated production tracking

- Competitive MOQ (from prototype to mass production)

- 24/7 technical support

Visit aoomtech.com to request a free project evaluation.