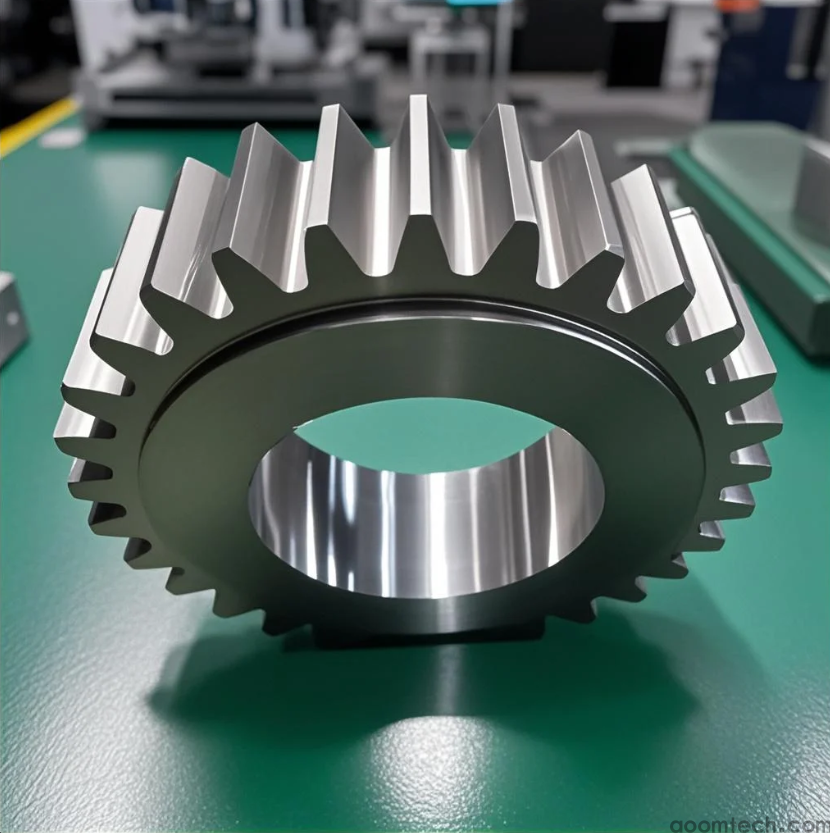

CNC Machining Worm Gears: Precision Solutions for Industrial Applications

As a leading CNC machining service provider, AOOM Technologies specializes in manufacturing high-precision worm gears for diverse industrial needs. This article explores the technical nuances, quality standards, and value-added services that set our solutions apart.

What Are CNC Machined Worm Gears?

Worm gears are specialized power transmission components consisting of a threaded screw (worm) meshing with a toothed wheel. Our CNC machining process ensures:

- Accurate tooth profiles with .005mm tolerance

- Optimal surface finishes (Ra .8μm achievable)

- Material integrity through controlled machining parameters

AOOM's Manufacturing Capabilities

Our 5-axis CNC centers produce worm gears with:

- Diameters from 10mm to 800mm

- Module range: .5 to 10

- Materials: Carbon steel, stainless steel, brass, and engineered plastics

- Secondary processes: Heat treatment, grinding, and anti-corrosion coatings

Why Choose AOOM for Your Worm Gear Production?

We address critical industry pain points through:

- Precision engineering: ISO 1328-1:2013 compliant gear geometry

- Rapid prototyping: 3-5 day lead time for design validation

- Quality assurance: 100% dimensional inspection with CMM

- Custom solutions: Modified tooth profiles for noise reduction

Contact AOOM Technologies at www.aoomtech.com to discuss your worm gear requirements with our engineering team.

Write your message here and send it to us