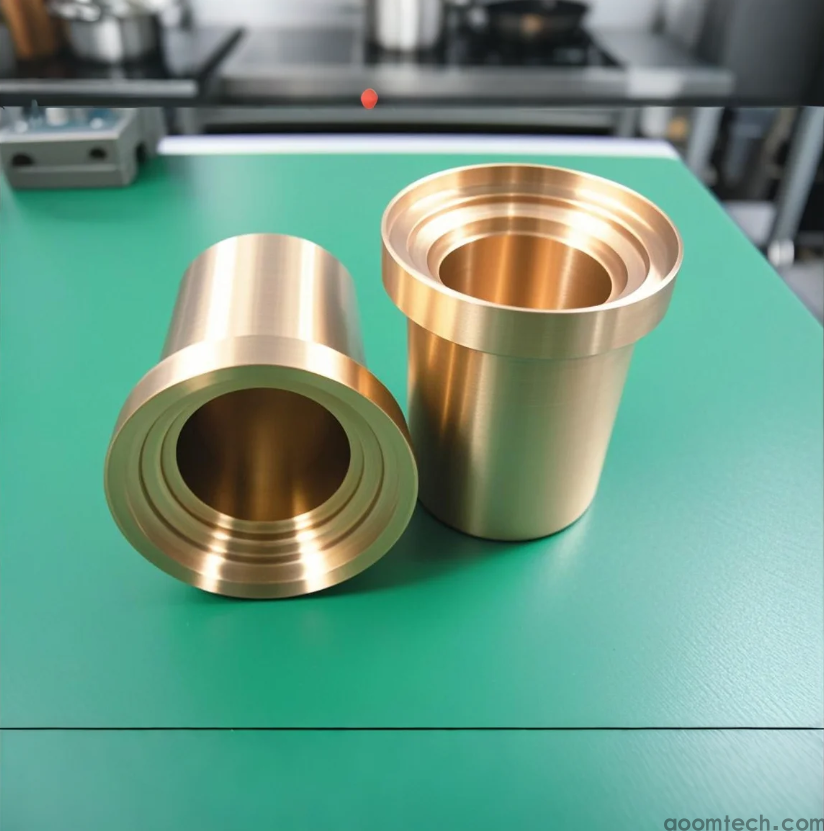

CNC Machining Bronze: Precision, Durability, and Custom Solutions

Bronze is a versatile alloy widely used in industries ranging from aerospace to marine applications due to its exceptional corrosion resistance, machinability, and wear properties. At AOOM, we specialize in CNC machining bronze components with tight tolerances and complex geometries, meeting the highest industry standards.

Why Choose Bronze for CNC Machining?

Bronze alloys (e.g., C932, C954) offer unique advantages for precision parts:

- Corrosion Resistance: Ideal for marine and chemical environments.

- Low Friction: Perfect for bearings, bushings, and gears.

- Thermal Conductivity: Suitable for heat exchangers and electrical components.

Our CNC machining processes ensure minimal material waste and optimal surface finishes.

AOOM's Bronze Machining Capabilities

We leverage advanced 5-axis CNC mills and lathes to deliver:

- Tolerances as tight as ±.005mm

- Surface finishes up to Ra .4μm

- Prototype to mass production (1–10,000+ units)

Our engineers optimize toolpaths to prevent bronze's tendency to work-harden during machining.

Applications of CNC Machined Bronze Parts

Industries we serve:

- Aerospace: Valve components, landing gear parts

- Automotive: Bushings, thrust washers

- Industrial: Pump impellers, hydraulic fittings

View our case studies at aoomtech.com for real-world examples.

Partner with AOOM for Your Bronze Machining Needs

As an ISO 9001-certified manufacturer, AOOM combines material expertise with cutting-edge CNC technology. Request an instant quote or DFM analysis today to experience precision bronze machining tailored to your specifications.