Large-Scale CNC Machining Companies: Capabilities and Selection Guide

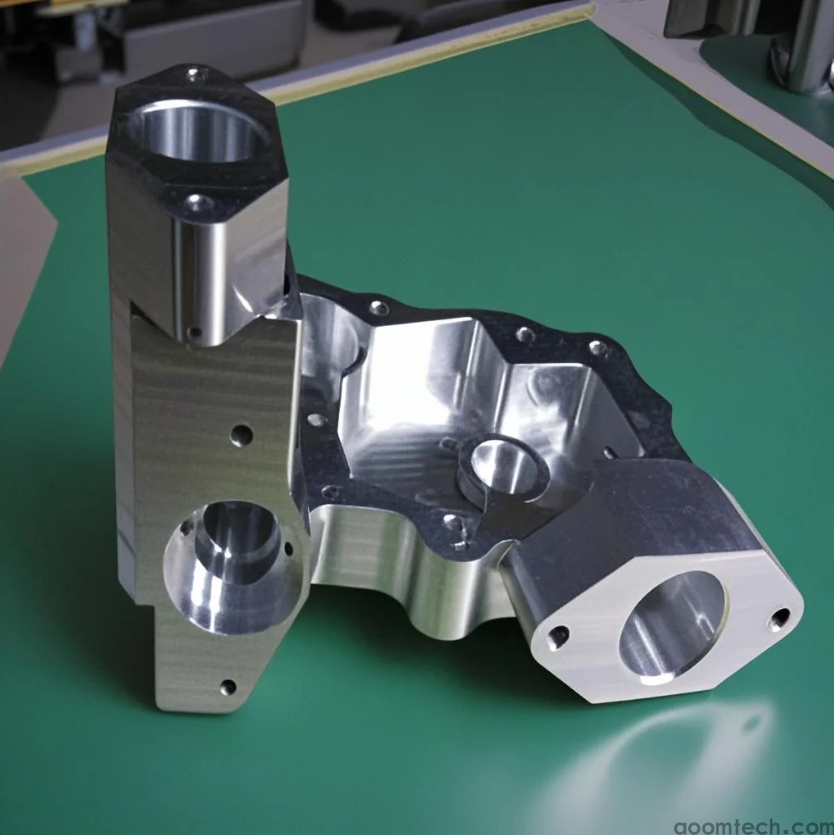

When sourcing large-scale CNC machining services, manufacturers and engineers need partners capable of handling complex projects with precision and efficiency. As an industry-leading CNC machining service provider, AOOM Technology offers insights into what distinguishes top-tier suppliers in this specialized field.

What Defines a Large-Scale CNC Machining Company?

True large-scale CNC machining companies operate with:

- Multiple large-format CNC machines (5-axis mills, horizontal machining centers)

- Advanced metrology equipment for quality control

- Dedicated engineering teams for complex projects

- Material inventory management systems

- ISO 9001 or AS910 certified quality systems

Key Advantages of Partnering with AOOM Technology

Our CNC machining services stand out through:

- 50+ CNC machines with work envelopes up to 4m×2m×1m

- ±.005mm repeatable machining accuracy

- In-house tooling and fixture design capabilities

- DFM (Design for Manufacturing) consultation included

- Prototype to production transition support

Industry Applications We Serve

AOOM Technology specializes in precision machining for:

- Aerospace structural components

- Automotive prototyping and production

- Medical device manufacturing

- Energy sector equipment

- Industrial automation systems

Selecting Your CNC Machining Partner

Evaluate potential suppliers on:

- Technical capabilities matching your project requirements

- Quality certifications and process documentation

- Material traceability and certifications

- Lead time reliability and production capacity

- Engineering support and communication

With our extensive machining capabilities and engineering expertise, AOOM Technology delivers precision components that meet the most demanding specifications. Contact our team to discuss your large-scale CNC machining requirements.