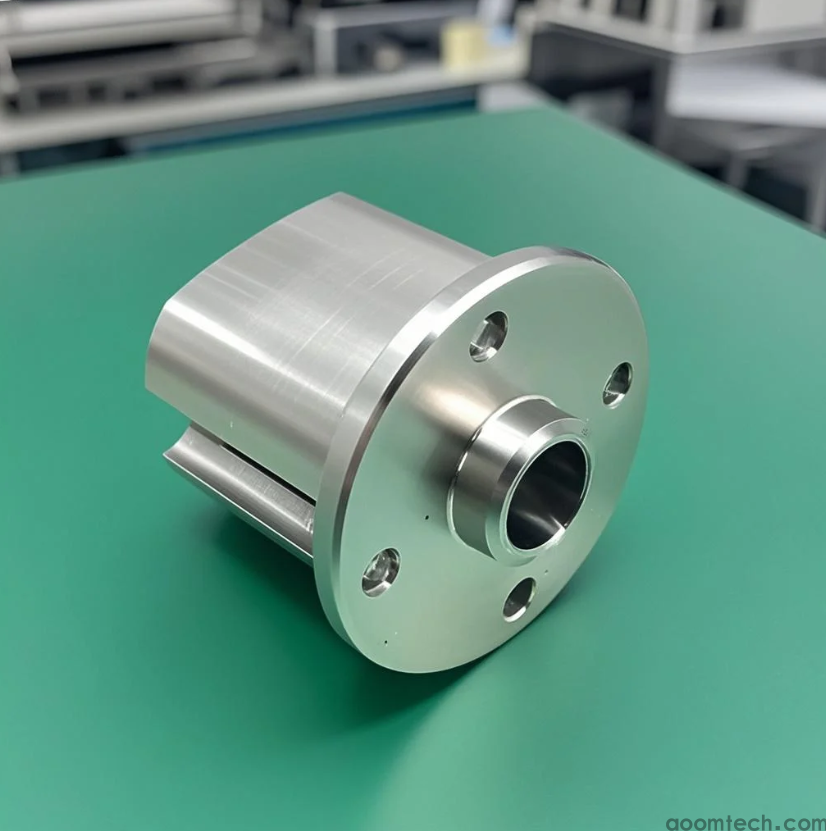

Steel CNC Machining Process

As a professional CNC machining service provider, AOOM Technology specializes in delivering high-precision steel components for industries ranging from aerospace to automotive. This article explores the critical aspects of steel CNC machining, addressing common challenges and showcasing our technical expertise.

Understanding Steel CNC Machining

Steel is one of the most widely used materials in precision manufacturing due to its exceptional strength and durability. The CNC machining process for steel involves advanced milling, turning, and drilling operations to create complex geometries with tight tolerances (typically ±.005mm). At AOOM, we utilize 5-axis CNC centers equipped with carbide tooling specifically designed for hardened steels.

Key Advantages of Our Steel Machining Capabilities

1. Material Expertise: We machine all steel grades including 304/316 stainless, tool steels (D2, H13), and alloy steels (414, 434)

2. Surface Finish Options: From Ra .8μm mirror finishes to textured surfaces for specific applications

3. Quality Assurance: In-house CMM inspection and ISO 9001-certified processes

Applications Across Industries

Our steel CNC components serve critical functions in:

- Hydraulic systems (valve bodies, pistons)

- Medical equipment (surgical instruments)

- Automotive transmissions (gears, shafts)

- Industrial machinery (bearing housings, fixtures)

Why Choose AOOM for Steel CNC Projects?

With 15+ years of machining experience, we combine German-origin CNC equipment with proprietary toolpath optimization software to deliver:

- 30% faster cycle times compared to industry standards

- 99.8% on-time delivery rate

- Full DFM support from our engineering team

Visit aoomtech.com to request a free project evaluation or download our steel machining capabilities brochure.