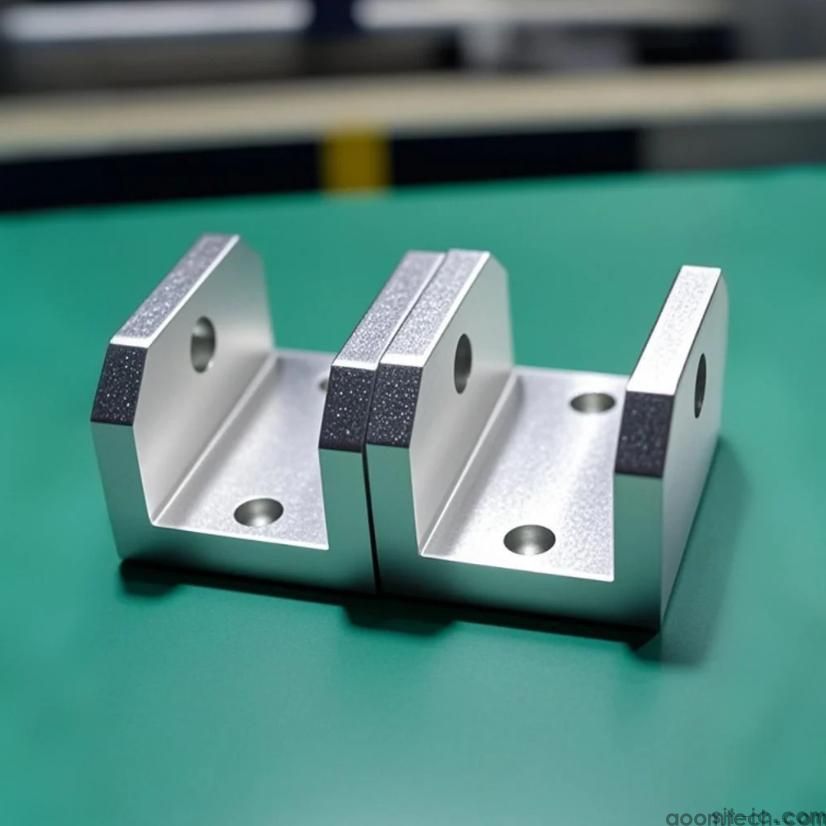

Precision Parts CNC Machining

What Is Precision Parts CNC Machining?

Precision parts CNC machining is a subtractive manufacturing process that uses computer-controlled machines to produce highly accurate and complex components with tight tolerances. This method is ideal for industries requiring exceptional dimensional accuracy, such as aerospace, medical devices, and automotive engineering. At AOOM, we specialize in delivering precision CNC machined parts that meet the strictest quality standards.

Key Advantages of Precision CNC Machining

1. Tight Tolerances: Achieve tolerances as low as ±.001" for critical applications.

2. Material Versatility: Compatible with metals (aluminum, titanium, stainless steel) and engineering plastics.

3. Surface Finish Excellence: Optional post-processing (e.g., anodizing, polishing) for enhanced functionality.

4. Scalability: Cost-effective for both prototypes and high-volume production.

AOOM’s Precision CNC Machining Capabilities

Our CNC precision machining services leverage advanced 3/4/5-axis machines, ISO 9001-certified workflows, and in-house metrology tools (CMMs, optical comparators) to ensure unmatched accuracy. We serve clients globally with rapid prototyping, custom fixturing, and full DFM support to optimize part performance and manufacturability.

Industries We Serve

• Aerospace: Engine components, landing gear parts.

• Medical: Surgical instruments, implantable devices.

• Automotive: Transmission systems, fuel injection parts.

• Electronics: Heat sinks, enclosures with EMI shielding.

Why Choose AOOM for Your Project?

With 15+ years of expertise, AOOM combines cutting-edge technology with rigorous quality control to deliver precision parts on time. Our team provides end-to-end solutions—from CAD/CAM programming to final inspection—ensuring every component meets your exact specifications. Contact us today for a free quote or DFM analysis.

Note: All processes adhere to international standards without compromising material integrity or design intent.