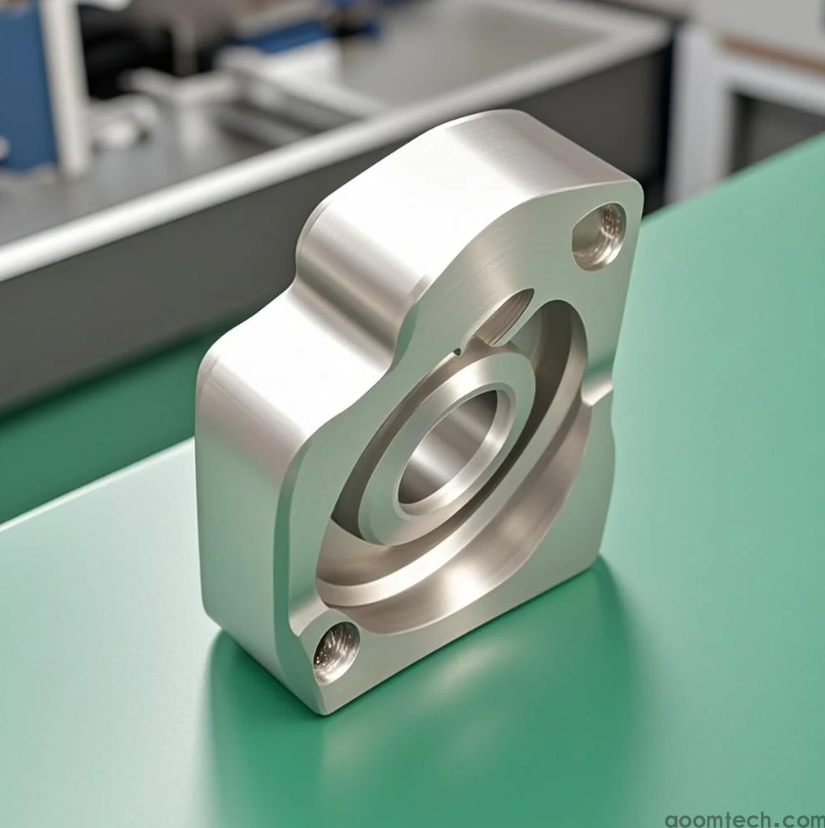

CNC Machining Medical Parts

In the highly regulated medical industry, CNC machining medical parts requires exceptional precision, material expertise, and strict compliance with international standards. As a leading CNC machining specialist, AOOM Technologies delivers mission-critical components for surgical instruments, implants, and diagnostic equipment.

Why Choose CNC Machining for Medical Components?

Medical-grade CNC Machining of Medical Parts demands:

- ±.005mm tolerances for perfect fitment

- Biocompatible materials (Ti-6Al-4V, 316L stainless steel, PEEK)

- Mirror finishes (Ra ≤ .2μm) to prevent bacterial adhesion

- Full traceability with material certifications

Our ISO 13485-certified facility combines 5-axis milling and Swiss turning capabilities to meet these rigorous requirements.

Key Applications in Medical Device Manufacturing

We specialize in:

- Orthopedic implants (knee/hip joints, spinal fixation devices)

- Minimally invasive surgical tool components

- Dental prosthetics and abutments

- Imaging system precision parts

Each component undergoes rigorous CMM inspection and cleanroom packaging.

AOOM's Competitive Advantages

Unlike generic machining shops, we offer:

- Dedicated medical production lines with contamination control

- FDA/CE compliant documentation packages

- Single-source solutions from prototyping to volume production

- 30% faster lead times through optimized workflows

Our engineers work closely with medical OEMs to overcome unique manufacturing challenges.

Request a quote for your medical CNC project at www.aoomtech.com, where precision meets life-saving innovation.