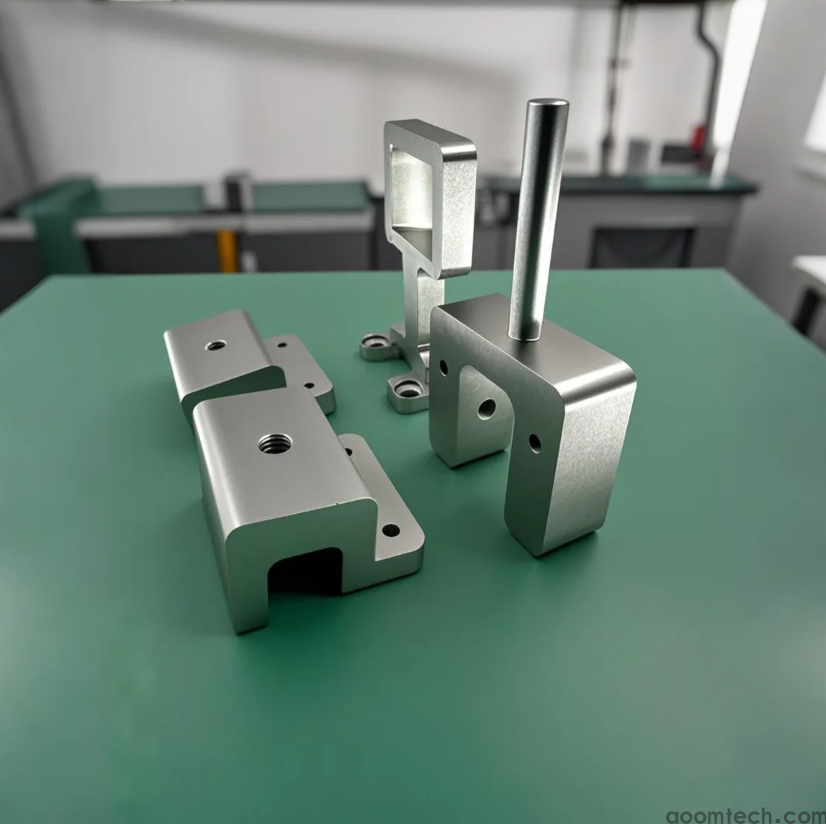

CNC Aluminum Alloy Machining: Precision Solutions for Industrial Applications

As a leading CNC machining service provider, AOOM Technologies specializes in delivering high-precision aluminum alloy machining solutions tailored to aerospace, automotive, and electronics industries. Our ISO-certified facility combines advanced 5-axis CNC systems with proprietary surface treatment techniques to achieve ±.005mm tolerances.

Why Choose CNC Machining for Aluminum Alloy Components?

Aluminum alloys (including 6061, 7075, and 5052) offer exceptional strength-to-weight ratios ideal for structural applications. Our CNC aluminum machining process leverages high-speed spindles (up to 20,000 RPM) and custom tooling to prevent material deformation while achieving mirror finishes (Ra .4μm).

Technical Capabilities at AOOM Technologies

• Material Expertise: Anodizing, hard coating, and chemical conversion treatments

• Precision Equipment: 15+ Mori Seiki NVX500 machines with automated tool changers

• Quality Assurance: CMM inspection with 3D scanning for GD&T validation

Industry-Specific Applications

From drone frames to medical device housings, our CNC aluminum machining services support rapid prototyping (3-day lead time) and large-scale production (monthly capacity: 500,000+ parts). All components undergo strict DFM analysis to optimize cost-efficiency.