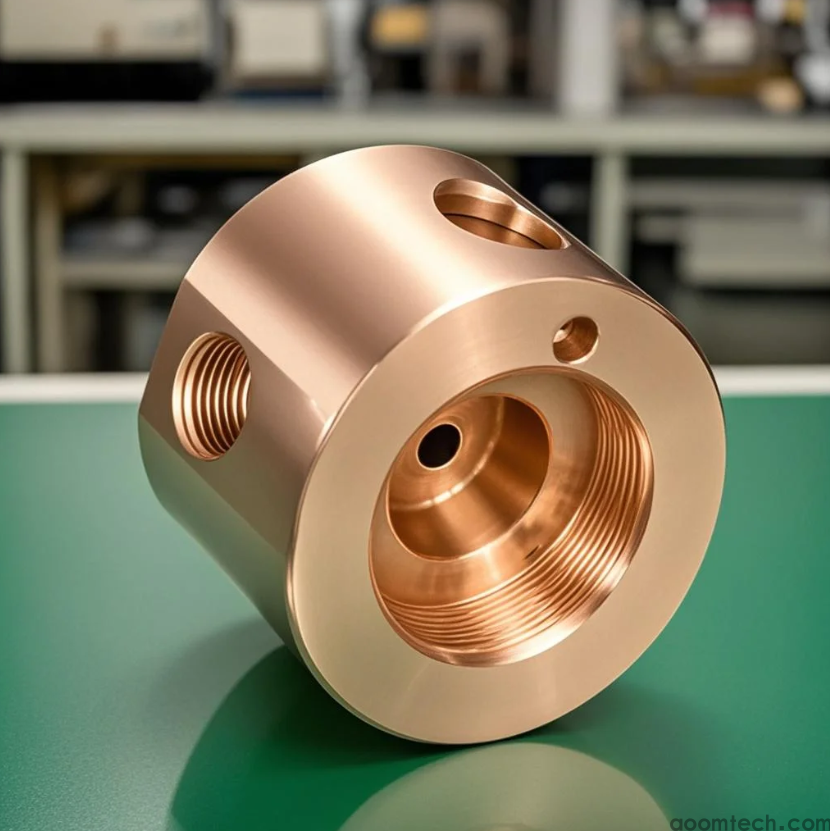

CNC Machining Copper Parts

Copper is one of the most widely used materials in CNC machining due to its excellent electrical conductivity, thermal conductivity, and corrosion resistance. At AOOM Technologies, we specialize in precision CNC machining of copper parts for various industries, delivering high-quality components with tight tolerances and superior surface finishes.

Why Choose Copper for CNC Machining?

Copper offers unique advantages that make it ideal for many applications:

- Exceptional electrical conductivity (second only to silver)

- Superior thermal conductivity

- Excellent corrosion resistance

- Good machinability with proper tooling

- Antimicrobial properties

- Attractive appearance

Our CNC Machining Capabilities for Copper Parts

AOOM Technologies provides comprehensive CNC machining services for copper components:

- 3-axis, 4-axis, and 5-axis CNC milling

- CNC turning and Swiss machining

- High-speed machining for complex geometries

- Micro-machining for small precision parts

- Secondary operations including deburring and surface finishing

Common Applications of CNC Machined Copper Parts

Our CNC machined copper components serve various industries:

- Electronics: Heat sinks, connectors, busbars, and electrical contacts

- Automotive: Wiring components, sensors, and cooling system parts

- Medical: Surgical instruments and diagnostic equipment components

- Aerospace: Electrical systems and thermal management components

- Industrial: Valves, fittings, and machinery components

Challenges in CNC Machining Copper and Our Solutions

While copper offers many benefits, it presents some machining challenges that our experts have mastered:

- Work hardening: We use sharp tools and proper cutting parameters to prevent material hardening

- Galling and built-up edge: Our technicians select optimal tool coatings and cutting fluids

- Thermal expansion: We account for copper's thermal properties in our machining processes

- Surface finish requirements: We employ specialized techniques to achieve mirror-like finishes when needed

Quality Assurance for CNC Machined Copper Parts

At AOOM Technologies, quality is our top priority. Our quality control measures include:

- First-article inspection and in-process quality checks

- Advanced metrology equipment for dimensional verification

- Material certification and traceability

- Surface roughness measurement

- Electrical conductivity testing when required

Why Choose AOOM Technologies for Your Copper CNC Machining Needs?

When you partner with AOOM Technologies for your copper machining projects, you benefit from:

- Extensive experience with copper and copper alloys

- State-of-the-art CNC machining equipment

- Skilled machinists and engineers

- Competitive pricing and fast turnaround times

- Custom solutions tailored to your specific requirements

Whether you need prototype quantities or high-volume production, our team is ready to deliver precision CNC machined copper parts that meet your exact specifications. Contact us today to discuss your project requirements.