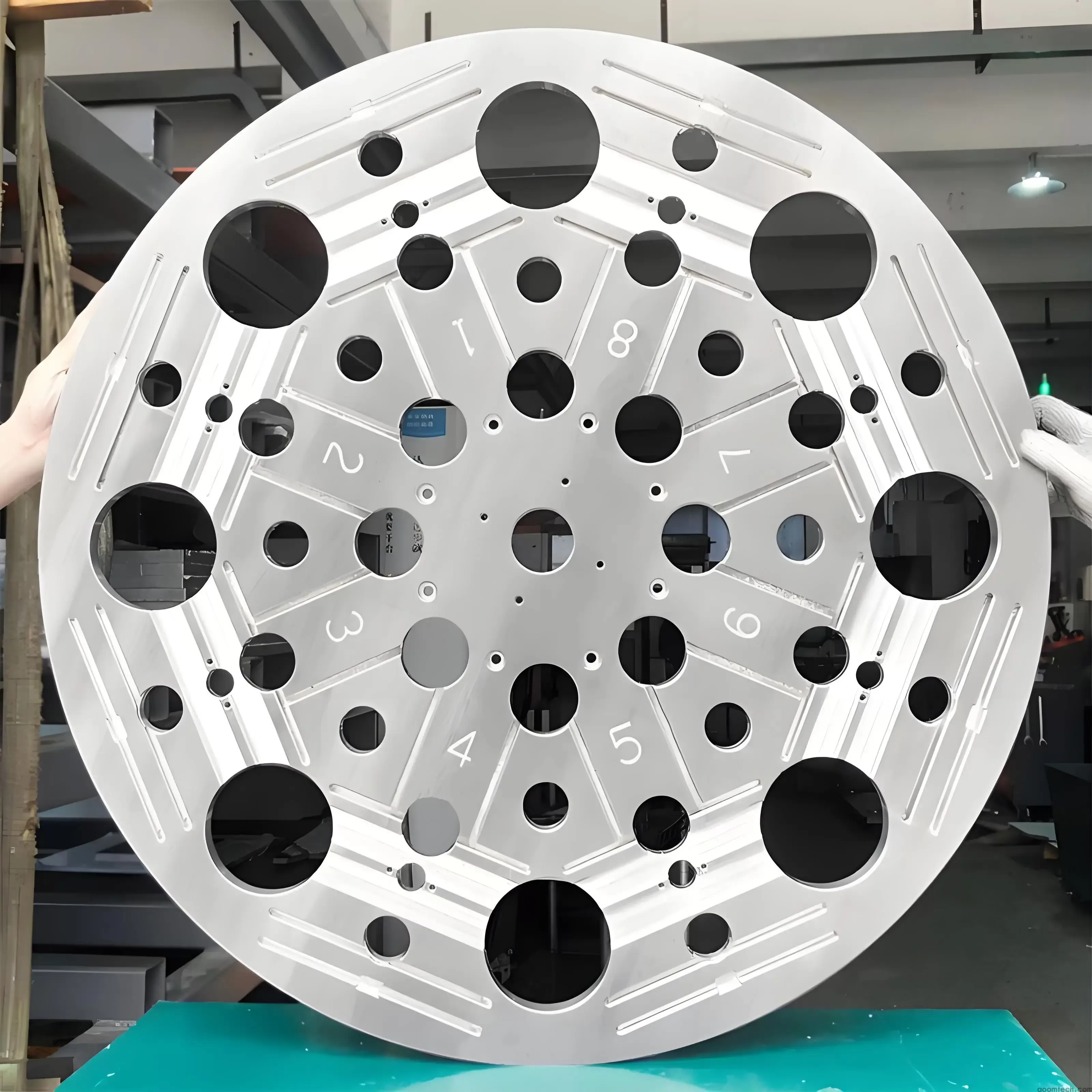

CNC Precision Large-Part Machining

In industrial manufacturing, CNC precision large-part machining represents the pinnacle of technical capability, requiring specialized equipment, advanced programming, and rigorous quality control. As a leading provider at AOOM Technologies, we've mastered the art of producing massive yet precision-engineered components for aerospace, energy, and heavy equipment sectors.

Technical Challenges in Large-Part Machining

Machining oversized components presents unique challenges that standard CNC shops cannot address:

- Structural rigidity requirements for machine tools

- Thermal compensation systems for consistent accuracy

- Custom fixturing solutions for workpiece stability

- Advanced toolpath strategies for extended tool life

Our Capabilities at AOOM Technologies

Our facility features CNC machining centers specifically designed for large-part production:

- 5-axis gantry mills with 8m x 4m x 3m working envelopes

- High-torque spindles (80+ HP) for heavy material removal

- Laser measurement systems for real-time compensation

- On-machine probing for dimensional verification

Material Expertise

We regularly machine challenging materials for large components:

- High-strength aluminum alloys for aerospace frames

- Maraging steels for defense applications

- Super alloys (Inconel, Hastelloy) for energy sector

- Engineering plastics for industrial applications

Quality Assurance Protocol

Every large component undergoes our 7-stage inspection process:

- First-article inspection with CMM

- In-process dimensional checks

- Surface finish verification

- Material certification review

- Final assembly trial (when applicable)

- Documentation package preparation

- Shipping protection assessment

With our CNC precision large-part machining capabilities, AOOM Technologies delivers components that meet the most demanding specifications while maintaining competitive lead times. Our engineering team works closely with clients from design phase through final delivery, ensuring optimal manufacturability without compromising performance requirements.