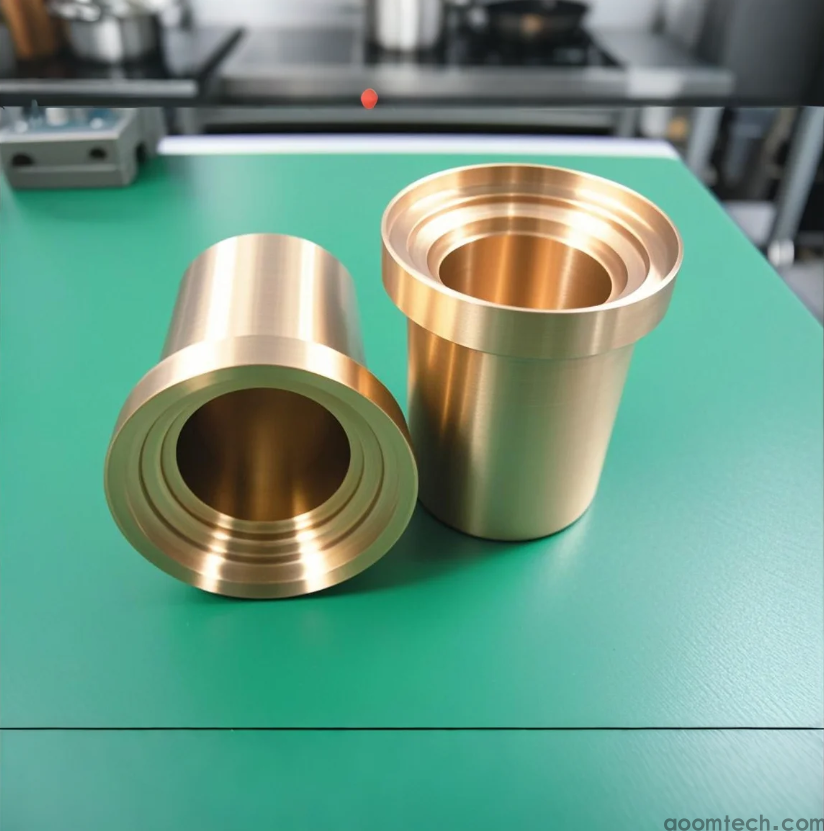

Copper Parts CNC Machining Customization

In modern manufacturing, copper parts CNC machining customization has become an essential service for industries requiring high-precision, complex-shaped components with excellent electrical and thermal conductivity. As a leading CNC machining service provider, AOOM Technologies specializes in delivering customized copper parts that meet the most demanding specifications.

Why Choose CNC Machining for Copper Parts?

Copper presents unique machining challenges due to its softness and tendency to stick to cutting tools. Our advanced CNC machines and specialized tooling overcome these challenges to produce:

- Precision electrical components with tight tolerances

- Heat exchangers and thermal management systems

- Custom bushings, bearings, and wear parts

- Complex geometries for industrial applications

Our Copper CNC Machining Capabilities

AOOM Technologies offers comprehensive copper machining services including:

- 3/4/5-axis CNC milling for complex 3D shapes

- CNC turning for precision cylindrical components

- Micro-machining for miniature copper parts

- Secondary operations (deburring, polishing, plating)

Quality Assurance in Copper Part Manufacturing

We implement strict quality control measures throughout the custom copper machining process:

- Material certification and traceability

- In-process dimensional inspections

- Surface finish verification

- Final comprehensive quality checks

Our ISO 9001-certified quality management system ensures every copper component meets your exact specifications and industry standards.

Applications of Custom CNC Machined Copper Parts

Our precision-machined copper components serve critical functions across multiple industries:

- Electronics: Connectors, terminals, and heat sinks

- Automotive: Electrical systems and cooling components

- Aerospace: Waveguides and electrical contacts

- Medical: Diagnostic equipment components

- Industrial: Bus bars and power distribution parts

At AOOM Technologies, we combine advanced CNC technology with copper machining expertise to deliver customized solutions that meet your specific requirements. Contact us today to discuss your copper parts project and benefit from our precision manufacturing capabilities.