CNC Aluminum Alloy Machining Price

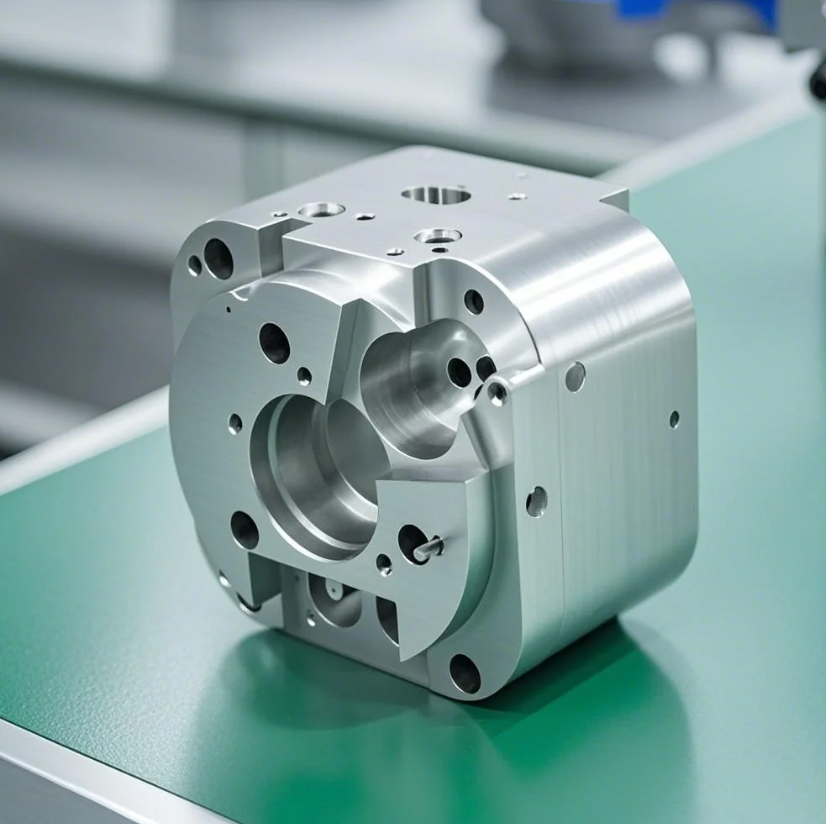

As a professional CNC machining service provider, AOOM Technology understands that CNC aluminum alloy machining price is one of the primary concerns for procurement managers, engineers, and business owners. This article will provide a comprehensive analysis of the factors affecting pricing and how AOOM delivers both quality and cost-effectiveness in aluminum machining services.

Factors Influencing CNC Aluminum Machining Costs

The price of CNC aluminum machining depends on several key factors:

- Material Grade: Different aluminum alloys (6061, 7075, 5052, etc.) have varying costs

- Part Complexity: Intricate designs require more machining time and specialized tooling

- Production Volume: Higher quantities typically reduce per-unit costs through economies of scale

- Surface Finishing: Additional processes like anodizing or powder coating add to the total cost

- Tolerance Requirements: Tighter tolerances demand more precise (and expensive) machining

AOOM's Competitive Pricing Strategy

At AOOM Technology, we've optimized our CNC aluminum machining processes to offer competitive pricing without compromising quality:

- Advanced 5-axis CNC machines for efficient material removal

- Bulk material purchasing for cost savings

- Automated production planning to minimize setup times

- Strict quality control to reduce waste and rework

How to Get an Accurate Quote

For precise CNC aluminum alloy machining price information, we recommend:

- Submit your CAD files through our online quotation system

- Specify material, quantity, and surface treatment requirements

- Our engineering team will analyze manufacturability and suggest cost-saving alternatives

- Receive a detailed quote within 24 hours

AOOM Technology combines state-of-the-art CNC equipment with extensive aluminum machining expertise to deliver high-quality parts at competitive prices. Visit our website at https://www.aoomtech.com/ to learn more about our capabilities or request a free quote today.